+86 13794985240

+86 13794985240

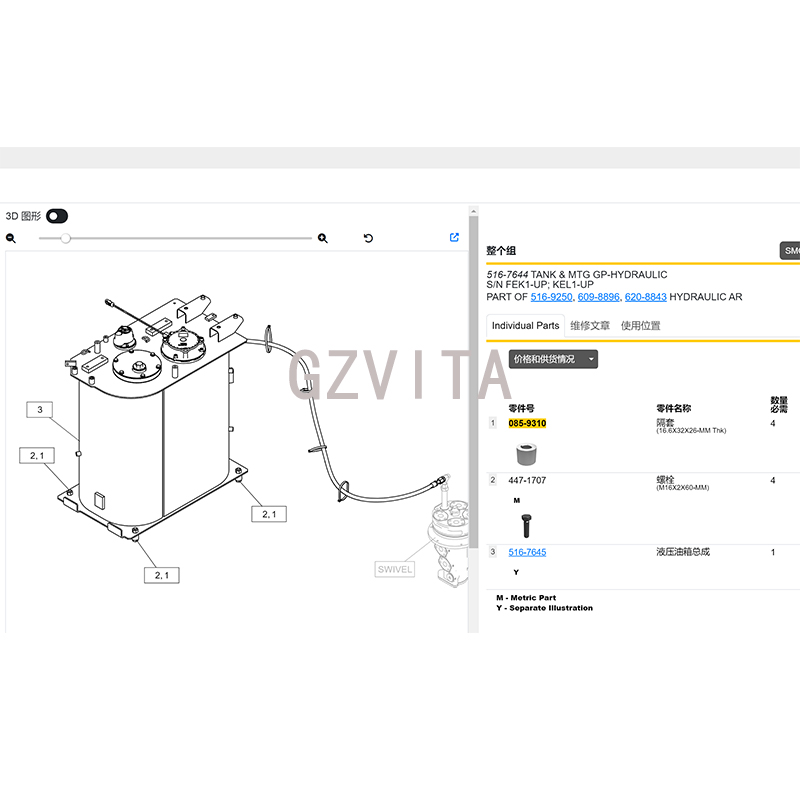

085-9310 Steel Spacer CAT312 320 307 Hex Head Bolt 447-1707

The Importance of Steel Spacers for a Hydraulic Tank on an Excavator

Steel spacers play a crucial role in the hydraulic systems of excavators, particularly in relation to the hydraulic tank. Here’s an overview of their importance:

- Structural Support

Stability: Steel spacers provide structural support to the hydraulic tank, ensuring that it remains securely mounted to the excavator’s frame. This stability is essential for maintaining the integrity of the hydraulic system during operation, especially in rugged environments.

Alignment: They help maintain proper alignment of the hydraulic tank with other components, which is critical for efficient fluid flow and system performance.

- Vibration Dampening

Reduction of Vibration: Excavators operate in dynamic environments where vibrations are common. Steel spacers can help absorb and dampen these vibrations, reducing the risk of damage to the hydraulic tank and associated components.

Longevity: By minimizing the impact of vibrations, steel spacers can extend the lifespan of the hydraulic tank and prevent premature wear and tear.

- Fluid Management

Fluid Flow: Properly installed steel spacers can help ensure that the hydraulic tank is positioned correctly, allowing for optimal fluid flow to and from the tank. This is vital for maintaining hydraulic pressure and system efficiency.

Preventing Contamination: By keeping the tank elevated and properly aligned, steel spacers can help prevent contamination from dirt and debris that may accumulate around the tank.

- Thermal Management

Heat Dissipation: Steel has good thermal conductivity, which can aid in dissipating heat generated by the hydraulic fluid. This is important for maintaining optimal operating temperatures and preventing overheating of the hydraulic system.

Temperature Regulation: Proper spacing can also allow for better airflow around the hydraulic tank, contributing to more effective cooling.

- Ease of Maintenance

Access for Inspection: Steel spacers can facilitate easier access to the hydraulic tank for maintenance and inspection. This is important for ensuring that the hydraulic system remains in good working condition and for performing routine checks.

Simplified Replacement: If the hydraulic tank needs to be replaced or serviced, having steel spacers in place can simplify the process, making it easier to remove and reinstall the tank.