+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

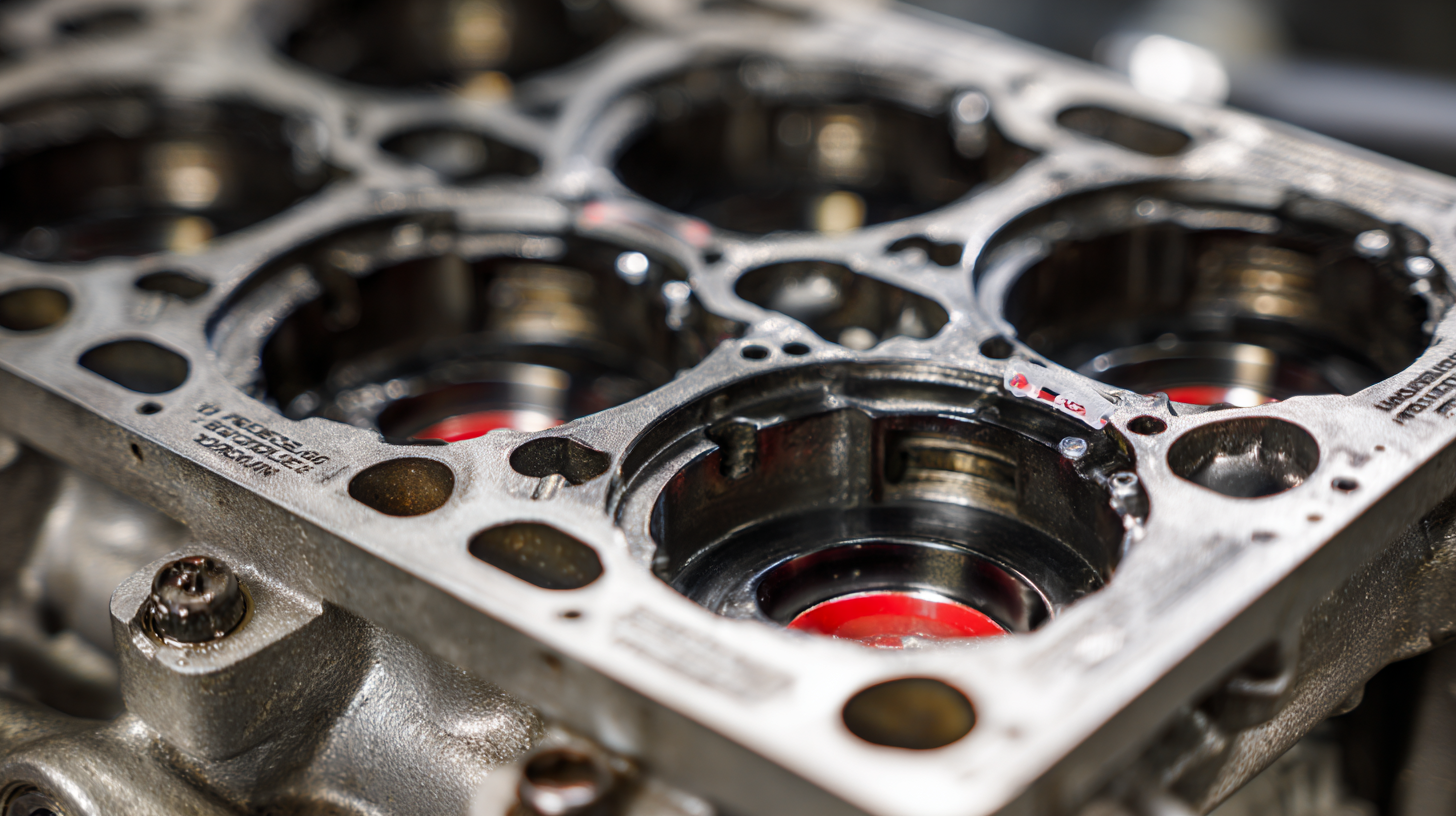

The Engine Cylinder Head plays a pivotal role in modern automotive design, serving as a critical component in engine performance and efficiency. According to a report by Markets and Markets, the global automotive engine cylinder head market is projected to reach $3.12 billion by 2025, driven by increasing demands for fuel efficiency and stringent emission regulations. However, despite advancements in technology, many manufacturers and automotive professionals remain unaware of the intricate features that can significantly influence engine performance and reliability. From advanced cooling channels and lightweight materials to integrated combustion chambers, the Engine Cylinder Head is a complex assembly that addresses numerous challenges faced by the automotive industry. Understanding these features not only aids in optimizing engine performance but also helps mitigate common problems such as overheating and increased emissions, ultimately enhancing vehicle longevity and efficiency.

When it comes to high-performance engine cylinder heads, several key characteristics can significantly enhance your vehicle's performance. One of the most critical features is the material construction of the cylinder head. High-performance heads often utilize lightweight aluminum alloys, which not only reduce overall engine weight but also improve heat dissipation. This is essential for maintaining optimal operating temperatures, which is vital for performance and longevity. Additionally, the use of advanced composite materials can further optimize strength while minimizing weight.

Another important characteristic to consider is the design of the combustion chamber. A well-engineered chamber shape can lead to better air and fuel mixing, resulting in more efficient combustion. Features such as larger intake and exhaust ports can also facilitate better airflow, which is crucial for maximizing horsepower and torque. Furthermore, some high-performance cylinder heads are designed with enhanced valve seats and guides to improve durability and heat resistance, making them ideal for racing applications. Overall, understanding these characteristics not only helps in making informed decisions but also enhances the engine's efficiency and performance on the road or track.

This chart illustrates the key characteristics of high-performance engine cylinder heads that are essential for optimal engine performance.

When it comes to ensuring the quality and reliability of engine cylinder heads, identifying trustworthy suppliers is paramount. To do this efficiently, businesses should focus on several key strategies. First, expanding the supplier base can help mitigate risks associated with supply chain disruptions. By diversifying sources, companies are better positioned to respond to unforeseen challenges, ensuring that their critical components remain accessible without compromising quality.

Another effective approach involves leveraging technology to enhance procurement processes. By utilizing advanced data management systems, businesses can better organize and access valuable information about potential suppliers, enabling more informed decision-making. This technology-driven strategy not only helps in identifying reliable suppliers but can also lead to improved operational efficiency and cost management. As companies navigate the complexities of supply chains, prioritizing these strategies will ultimately support smoother operations and foster long-term partnerships with dependable suppliers.

When evaluating the quality of engine cylinder heads, it is essential to consider several key strategies that can influence performance and longevity. One of the most critical aspects is the material used; aluminum and cast iron are common choices, with aluminum often providing better heat dissipation. According to industry reports, cylinder heads made from high-grade aluminum alloys can reduce overall engine weight by 10-20%, significantly enhancing vehicle performance.

Additionally, examine the manufacturing processes such as precision machining and casting techniques. Heads designed using advanced CNC machining methods typically exhibit higher accuracy and lower tolerances, resulting in better performance metrics. For instance, a study from the Engine Builders Association highlights that precision-engineered heads can improve airflow by as much as 15%, leading to increased horsepower and efficiency.

Tips: Always look for cylinder heads featuring reinforced areas around the valve seats, as this enhances durability under extreme conditions. Additionally, consider heads with improved port design for optimized airflow, which can dramatically affect engine responsiveness. Investing in quality cylinder heads is not only about performance but also about ensuring reliability and longevity in your engine's operation.

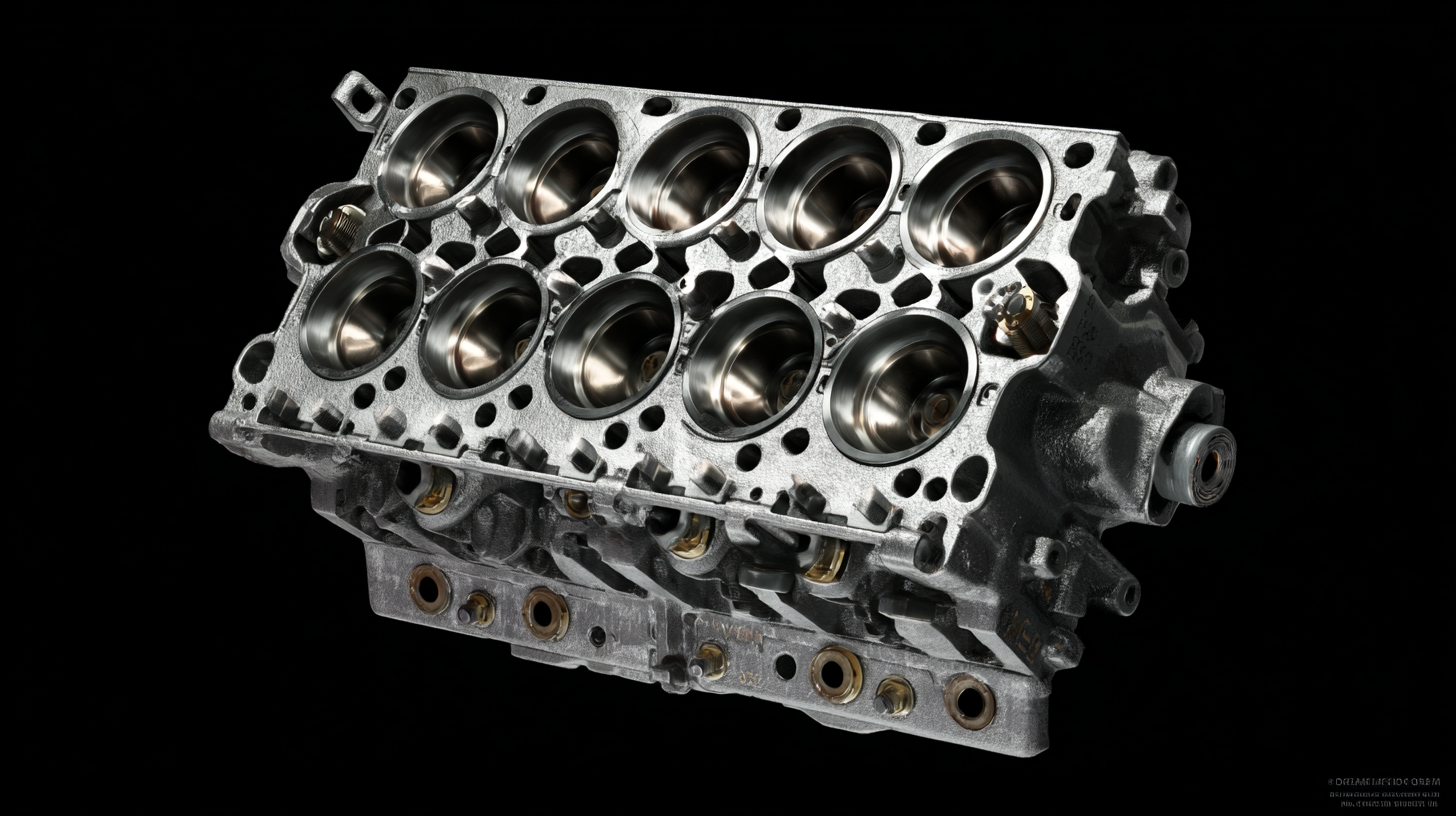

When it comes to engine performance, the selection of materials used in cylinder head manufacturing is paramount. The cylinder head is a critical component that influences not only the engine's efficiency but also its durability and power output. Engine builders often opt for materials such as aluminum and cast iron, each offering distinct advantages. Aluminum cylinder heads are lighter and provide excellent thermal conductivity, enabling better heat dissipation, which is essential for high-performance applications. On the other hand, cast iron heads are known for their strength and ability to withstand high pressures, making them suitable for heavy-duty engines.

Furthermore, the choice of materials impacts the overall design and function of the cylinder head. Features like integrated coolant passages and optimized porting are often influenced by the material's properties. Advanced materials, like composite alloys, are gaining popularity due to their ability to balance weight, strength, and thermal stability. By understanding the importance of material selection, engine designers can enhance performance while reducing weight, ultimately leading to improved fuel efficiency and emissions. Hence, the conversation around cylinder head materials is not just technical; it is essential for the evolution of engine design and performance.

Sourcing engine cylinder heads can present a complex array of challenges for builders aiming to maintain high-quality performance in their vehicles. One of the most significant pitfalls is the mismatch between engine cores and vehicle applications. According to industry reports, over 40% of engine builders experience sourcing issues that lead to performance inefficiencies due to this disconnect. It's crucial for builders to establish precise specifications when looking for engine heads, ensuring that the core meets the exact requirements of the intended application.

Additionally, the integration of associated tinware becomes an essential consideration. Reports indicate that neglecting to source compatible tinware can lead to serious installation complications and potential performance losses. Builders should prioritize suppliers who can provide comprehensive solutions that include both cylinder heads and their corresponding components. By carefully navigating these sourcing pitfalls, engine builders enhance their chances of achieving optimal performance and reliability in their projects.

| Feature | Description | Common Pitfalls |

|---|---|---|

| Material Composition | Many heads are made of aluminum or cast iron, affecting weight and heat dissipation. | Choosing the wrong material can lead to premature wear or overheating. |

| Port Design | Optimized designs improve airflow, boosting performance. | Poor port matching can hinder engine performance. |

| Cooling Features | Integrated cooling jackets help maintain optimal temperatures. | Inadequate design may lead to overheating and engine failure. |

| Valve Seat Insert Quality | High-quality inserts prevent wear and improve sealing. | Inferior materials can lead to grinding and oil leaks. |

| Compression Ratio | Higher ratios improve power but require higher octane fuel. | Misjudging ratio can cause engine knocking. |

| Guides and Seals | Quality valve guides and seals are essential for engine longevity. | Using poor-quality seals can lead to significant oil loss. |

| Tuning Capability | Easily tuned heads can significantly enhance performance. | Incompatibility with tuning equipment can limit enhancements. |

| Finishing Techniques | Surface finishing affects airflow and durability. | Poor finishes can lead to turbulence and reduced efficiency. |

| Weight Considerations | Lightweight designs improve handling but can compromise strength. | Too lightweight can cause structural failures under stress. |

| Installation Compatibility | Ensure the head fits the engine block without adapters. | Compatibility issues may lead to costly modifications. |