+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

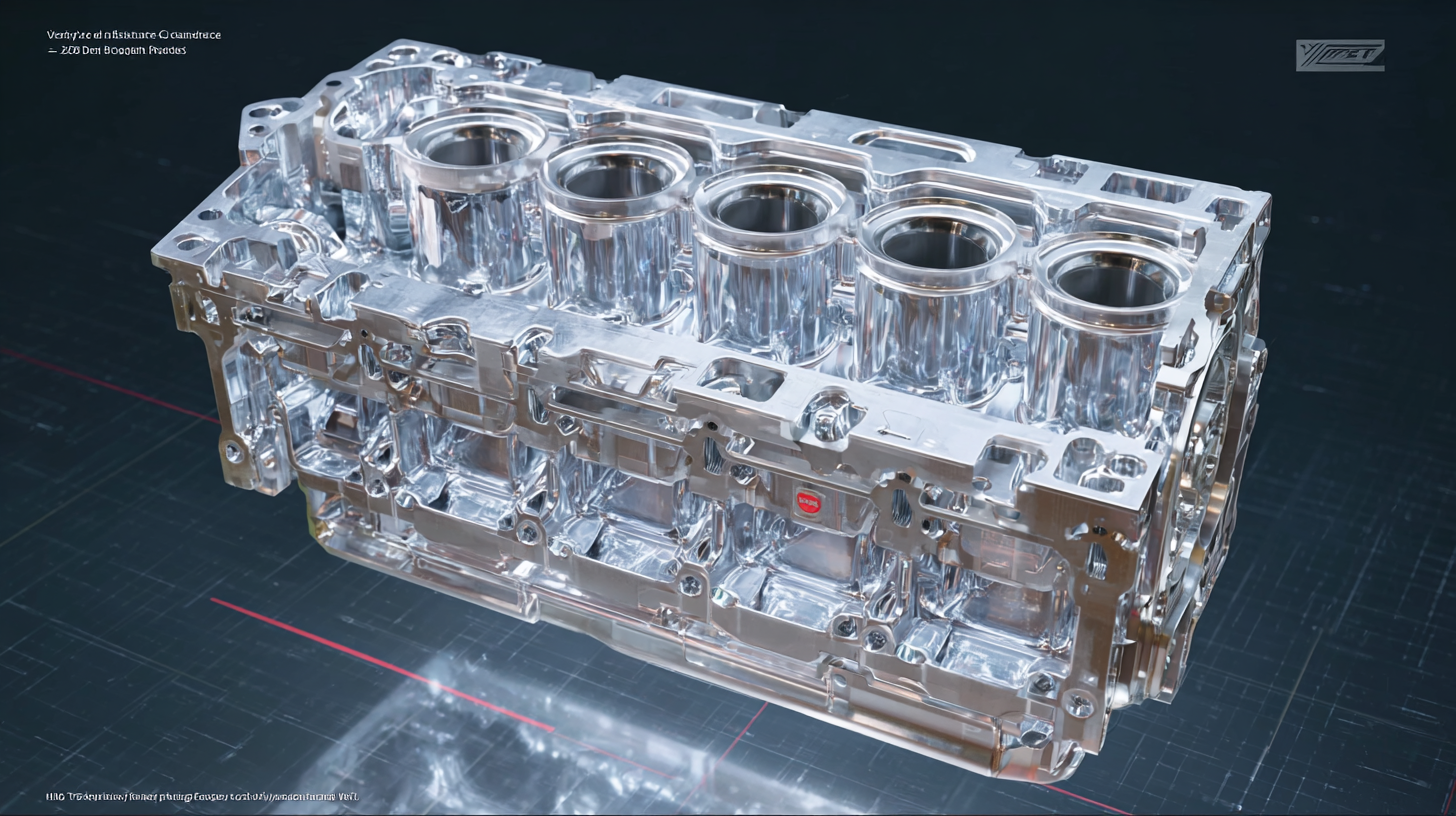

In the ever-evolving landscape of automotive technology, the engine cylinder block remains a cornerstone component that significantly influences a vehicle's performance, efficiency, and durability. As we look ahead to 2025, innovations in engine cylinder blocks promise to reshape the way we understand engine design and functionality. This guide will explore the latest advancements, comparing materials, designs, and manufacturing techniques that contribute to enhanced performance and sustainability.

From lightweight alloys to integrated cooling systems, each innovation presents unique benefits that can optimize engine output while reducing weight and fuel consumption. Join us as we delve into the crucial elements of engine cylinder block technology, assessing their potential impacts on the automotive industry and helping you stay informed about the future of engine performance.

As we approach 2025, the automotive industry is on the brink of significant advancements in engine cylinder blocks. These innovations are crucial for enhancing engine performance, efficiency, and sustainability. The demand for lightweight materials, such as aluminum and advanced composites, is rising, with recent studies showing that reducing engine weight by just 10% can lead to up to a 6% improvement in fuel efficiency. This trend underscores the importance of partnering with high-quality suppliers who can provide cutting-edge materials and manufacturing techniques tailored for next-gen cylinder blocks.

Identifying reliable suppliers is more essential than ever. According to industry data, companies that collaborate with top-tier suppliers can achieve up to 20% faster time-to-market for new engine technologies. An effective supplier can leverage advanced manufacturing processes, including 3D printing and precision machining, to produce cylinder blocks that meet stringent performance and durability standards. As manufacturers look to innovate for a competitive edge, establishing strategic relationships with specialists in engine components will be key to capitalizing on the emerging opportunities in the automotive landscape.

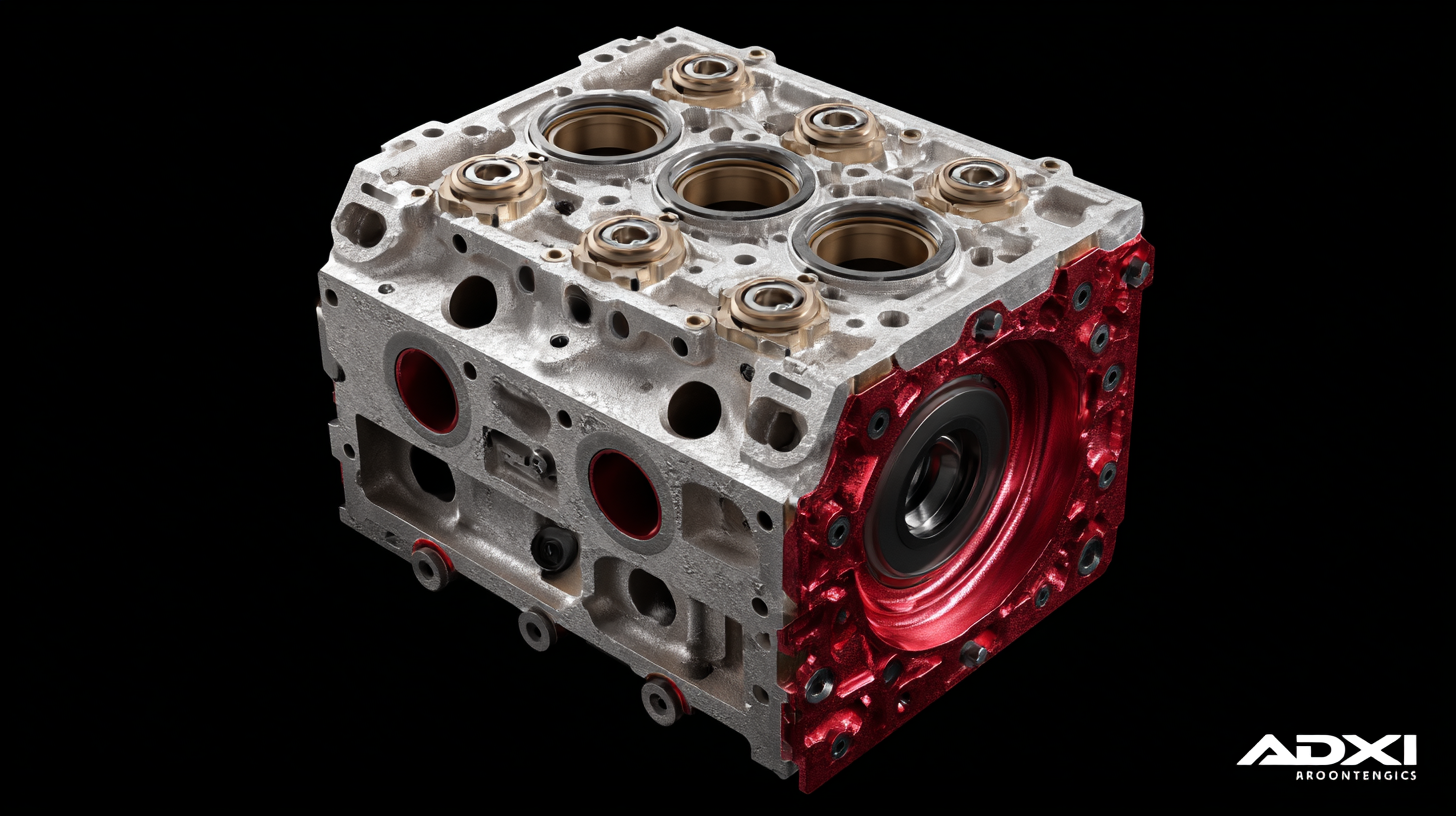

When selecting a supplier for engine cylinder blocks, several key features should be at the forefront of your decision-making process. First and foremost, consider the supplier’s manufacturing capabilities. Advanced technologies like precision machining and additive manufacturing can significantly enhance performance and longevity. A supplier who invests in modern technology will likely produce higher quality cylinder blocks that can withstand extreme conditions.

Another crucial aspect to examine is the supplier’s reputation and track record in the industry. Look for suppliers with certifications and positive reviews from previous clients. This can provide insights into their reliability and the satisfaction of their existing customer base. A strong track record often indicates a commitment to quality and innovation, essential for staying competitive in the rapidly evolving automotive landscape.

Tip: Don’t hesitate to ask potential suppliers about their Research and Development initiatives. Suppliers who prioritize R&D are more likely to integrate new technologies and materials into their products, leading to improved performance and efficiency. Additionally, inquire about their customer support services, as ongoing communication and assistance are vital for a successful partnership.

This chart illustrates the advancements in engine cylinder block technologies based on key features that enhance performance, efficiency, and durability. The data reflects the estimated adoption rates of these innovations among manufacturers by 2025.

When it comes to optimizing engine solutions, the reputation of your suppliers plays a crucial role. Evaluating supplier performance not only ensures the quality of engine cylinder blocks but also impacts your overall engine efficacy. A supplier with a solid track record will likely offer innovative materials, advanced manufacturing techniques, and reliable customer support. Look for suppliers that have consistently received positive feedback from other manufacturers in the industry. Their ability to deliver on promises directly contributes to your engine's performance and longevity.

**Tips:** One effective method to assess a supplier’s reputation is to request case studies or testimonials from previous clients. This can provide valuable insights into their service quality and product reliability. Additionally, consider attending industry trade shows where you can network with other professionals and glean firsthand experiences about various suppliers.

Monitoring a supplier’s performance over time is also essential. Regularly review metrics such as delivery times, defect rates, and responsiveness to issues. Utilizing these evaluations can help you make informed decisions and establish much stronger partnerships with suppliers who align with your goals for optimal engine solutions.

| Innovation Type | Key Features | Supplier Reputation | Performance Metrics | Sustainability Rating |

|---|---|---|---|---|

| Lightweight Materials | Enhanced fuel efficiency and reduced weight | High | 15% improved performance | A+ |

| Thermal Barrier Coatings | Increased durability and reduced thermal fatigue | Medium | 10% increase in longevity | B |

| Advanced Cooling Techniques | Effective heat management and higher performance | High | 20% efficiency gain | A |

| Integration of Smart Technologies | Real-time monitoring and data analytics | Very High | 15% reduction in emissions | A+ |

| Modular Engine Designs | Flexibility and ease of customization | Medium | 10% faster production rate | B+ |

In the competitive landscape of engine cylinder block suppliers, making informed choices between cost and quality has never been more crucial. As supply chains continue to experience disruptions, businesses are prioritizing resilience and efficiency in their procurement processes. Recent studies indicate that 79% of companies are focusing on developing more robust supplier relationships to mitigate risks, aligning their sourcing strategies with the evolving market demands. By using data-driven decision-making (DDDM), organizations can analyze supplier performance metrics, ensuring they choose partners that not only meet cost criteria but also uphold quality standards.

For instance, the trend of implementing AI in procurement has proven beneficial by increasing efficiency and reducing costs by up to 80%, allowing teams to focus on strategic supplier selection. Organizations are turning to centralized systems that streamline operations and facilitate better communication with suppliers. Additionally, advancements in technology enable companies to gather real-time data about market trends, empowering them to make informed choices based on comprehensive analyses rather than gut feelings. This approach not only optimizes their supply chains but also enhances overall performance, making it essential for businesses in the engine cylinder block industry to adopt such strategies in their supplier selection process.

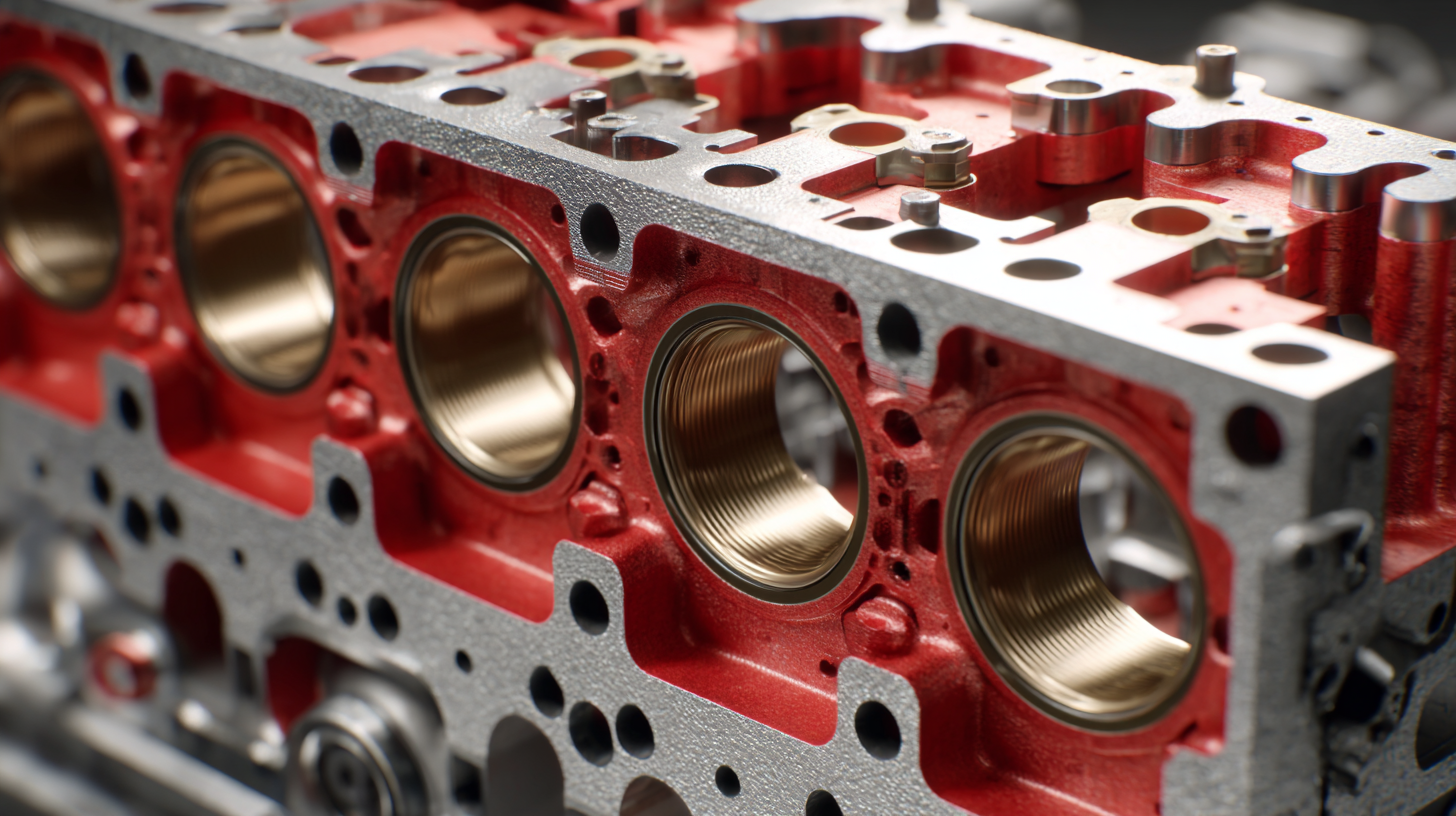

Engine cylinder block technology is rapidly evolving, driven by a combination of new energy vehicle trends and heightened environmental awareness. As we look towards 2025, it's critical that suppliers focus on innovation to optimize performance and efficiency. The shift towards electrification presents a unique opportunity for manufacturers to rethink their approaches, not just in terms of materials but also in design and manufacturing processes. Embracing lightweight materials and advanced manufacturing techniques can lead to enhanced engine performance, which is crucial for meeting the demands of modern automotive markets.

Supplier engagement strategies are also key in navigating this changing landscape. Companies should prioritize collaboration with technology providers to stay ahead of advancements that can influence cylinder block production. By integrating predictive analytics and IoT capabilities, suppliers can improve their product offerings while optimizing the supply chain. The recent comparisons of traditional and new energy vehicle industry chains highlight areas of growth and potential. As the market for engine cylinder blocks continues to evolve, leveraging these trends will be fundamental for maximizing performance in the years to come.