+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

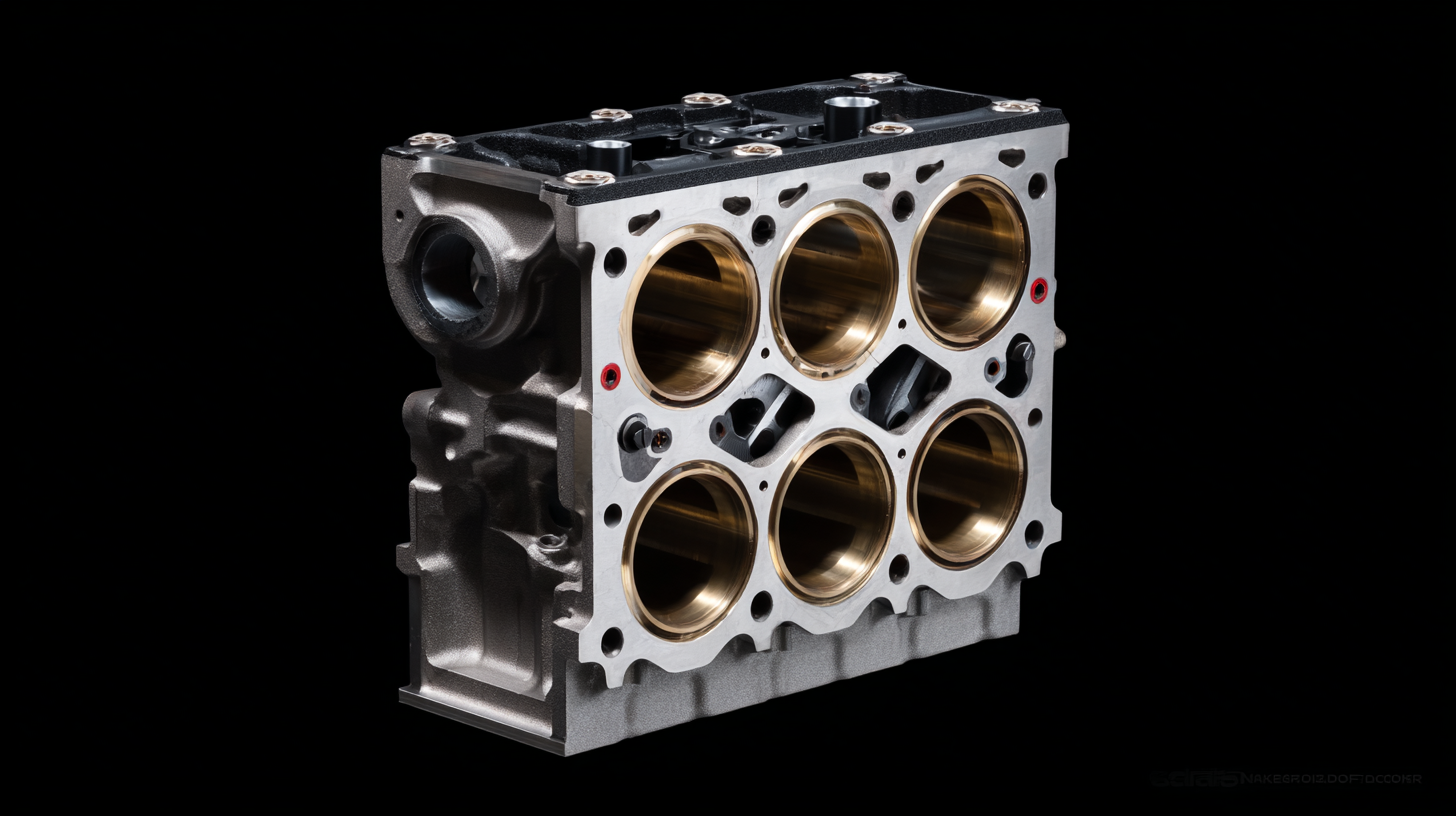

The Engine Cylinder Block serves as the fundamental structure that houses the engine's cylinders, playing a crucial role in the overall performance and efficiency of an engine. Recent industry reports indicate that advancements in materials and manufacturing processes have significantly contributed to the evolution of engine cylinder blocks, enhancing their strength and reducing weight.

For instance, high-performance engines often utilize aluminum alloy blocks, which can weigh up to 30% less than traditional cast iron blocks while providing comparable rigidity. Furthermore, according to the Society of Automotive Engineers (SAE), optimizing the design of the engine cylinder block can lead to improvements in thermal efficiency of up to 10%, directly impacting fuel consumption and emissions. As vehicle manufacturers strive to meet increasingly stringent environmental regulations, understanding the technical parameters of engine cylinder blocks—such as their weight, material composition, and cooling efficiency—becomes essential for achieving peak engine performance.

For instance, high-performance engines often utilize aluminum alloy blocks, which can weigh up to 30% less than traditional cast iron blocks while providing comparable rigidity. Furthermore, according to the Society of Automotive Engineers (SAE), optimizing the design of the engine cylinder block can lead to improvements in thermal efficiency of up to 10%, directly impacting fuel consumption and emissions. As vehicle manufacturers strive to meet increasingly stringent environmental regulations, understanding the technical parameters of engine cylinder blocks—such as their weight, material composition, and cooling efficiency—becomes essential for achieving peak engine performance.

The optimal performance of an engine is heavily influenced by the design and material of the engine cylinder block. Key technical specifications that contribute to this performance include the block's material composition, wall thickness, and cooling system integration. According to a report by the Society of Automotive Engineers (SAE), aluminum blocks offer superior thermal conductivity and weight reduction, leading to a weight savings of approximately 30% compared to traditional cast iron. This reduction not only enhances fuel efficiency but also improves power-to-weight ratio, essential for modern performance vehicles.

Another critical specification is the wall thickness of the cylinder block, which impacts strength and coolant flow. Research shows that blocks with a wall thickness optimized for thermal expansion can significantly reduce the risk of engine knock and improve longevity. Moreover, the integration of advanced cooling features, such as in-block coolant passages, can enhance heat dissipation, allowing for sustained high-performance operation. A report from J.D. Power indicates that engines with superior thermal management can achieve up to 10% improved efficiency, which is a compelling statistic for manufacturers aiming to meet stringent emissions regulations while maximizing performance outcomes.

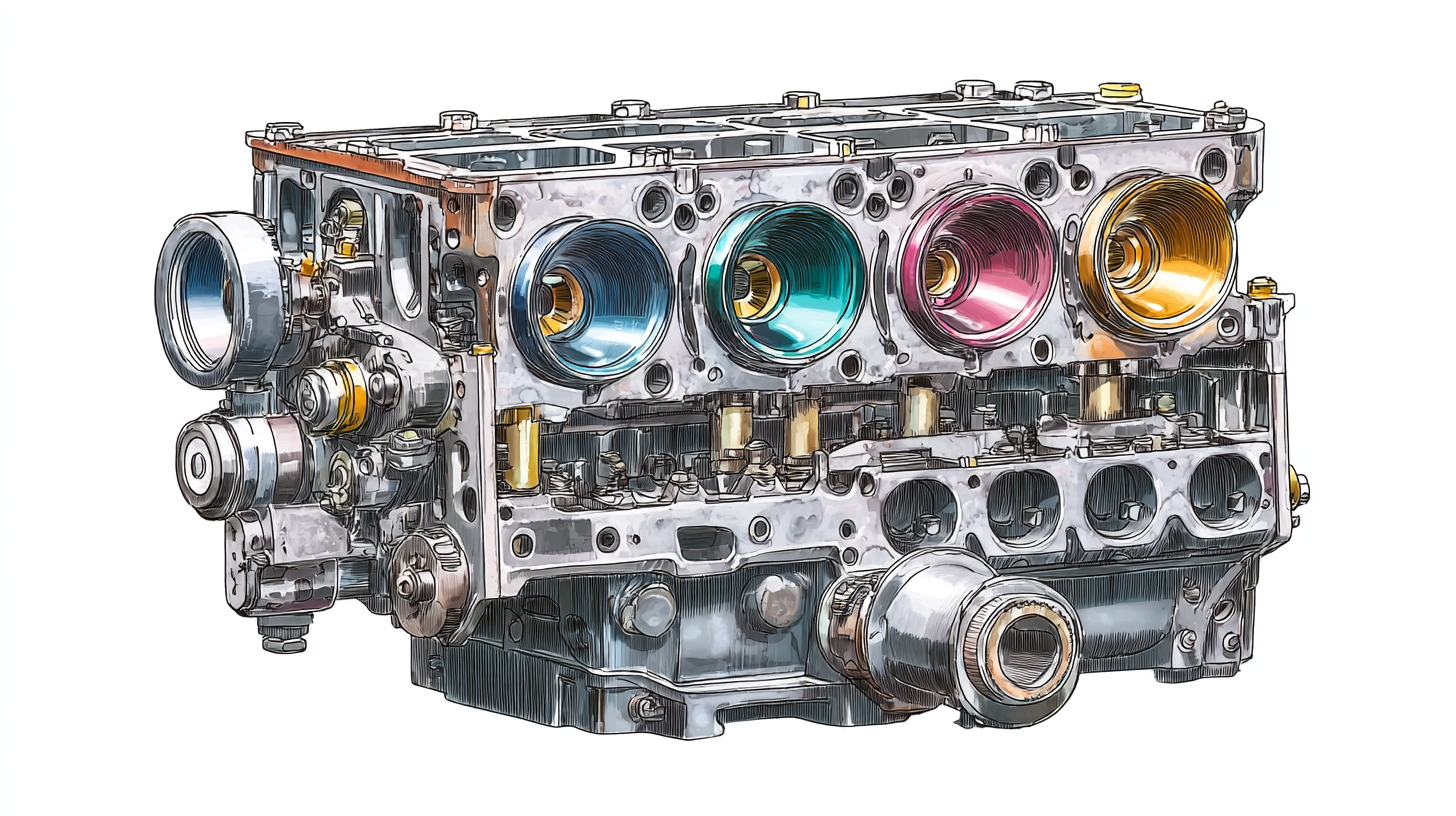

The materials used in engine cylinder blocks play a crucial role in determining engine performance, durability, and overall efficiency. In recent studies, various materials such as cast iron, aluminum, and advanced composites have been compared for their distinctive properties. Cast iron, known for its strength and wear resistance, is traditionally favored for heavy-duty applications. However, aluminum has gained popularity due to its lightweight nature, which enhances fuel efficiency and performance while reducing emissions. This comparison is invaluable as automakers seek to strike a balance between performance and environmental impact.

Tips for performance enhancement include considering the specific requirements of your engine. For high-performance applications, lightweight materials like aluminum or composite structures may offer a significant advantage. Additionally, addressing cooling efficiency is paramount; materials with better thermal conductivity can play a significant role in maintaining optimal engine temperatures.

Moreover, the impact of additives and biofuels on combustion characteristics continues to be an area of active research. Understanding how different materials in the cylinder block interact with varying fuel types can help engineers tailor designs for improved efficiency and lower emissions. Staying informed about these developments can lead to smarter choices in engine design and usage.

| Material | Weight (kg) | Thermal Conductivity (W/m·K) | Cost per kg (USD) | Strength (MPa) | Corrosion Resistance |

|---|---|---|---|---|---|

| Cast Iron | 70 | 45 | 2.00 | 250 | Good |

| Aluminum Alloy | 50 | 205 | 3.00 | 300 | Very Good |

| Steel | 60 | 45 | 1.80 | 500 | Fair |

| Magnesium Alloy | 40 | 160 | 4.50 | 280 | Poor |

| Composite Material | 30 | 120 | 5.00 | 350 | Excellent |

When selecting the right engine cylinder block for your vehicle, several key factors need to be considered to ensure optimal performance. Firstly, the material of the cylinder block plays a crucial role. Most modern vehicles utilize cast iron or aluminum. Cast iron is known for its durability and ability to withstand high levels of heat and pressure, making it a popular choice for heavy-duty applications. On the other hand, aluminum is lighter and offers better thermal efficiency, which can enhance the overall performance and fuel efficiency of your vehicle.

Another important consideration is the design and construction of the cylinder block. Features such as the block's bore and stroke dimensions significantly impact engine output. Additionally, look for blocks with improved cooling channels or additional reinforcement, particularly if you plan on enhancing your engine’s performance through modifications. Understanding the specifications that suit your driving style and vehicle type is essential, whether you’re a casual driver or a performance enthusiast. By prioritizing these factors, you can make an informed decision that aligns perfectly with your vehicle needs.

The performance of an engine is intricately linked to the design factors of its cylinder block. A well-engineered cylinder block serves as the foundation for power generation, supporting critical components like the crankshaft and cylinder head. The precision in design not only influences thermal efficiency but also affects the overall weight and strength of the block, impacting the engine's responsiveness and durability. Proper consideration of materials, thickness, and dimensional accuracy plays a vital role; these elements can significantly enhance an engine's ability to handle increased pressures and temperatures.

Moreover, the integration of advancements, such as billet blocks, showcases how modern engineering practices optimize performance. By allowing for tailored designs that meet specific performance benchmarks, builders can push beyond conventional limits. Factors like cylinder sleeve installation and the interface between the cylinder block and other components are crucial for maintaining performance integrity. Understanding these design nuances enables builders to create robust engines that deliver not only enhanced power but also reliability, ensuring that every performance-oriented vehicle can thrive on the track or road.

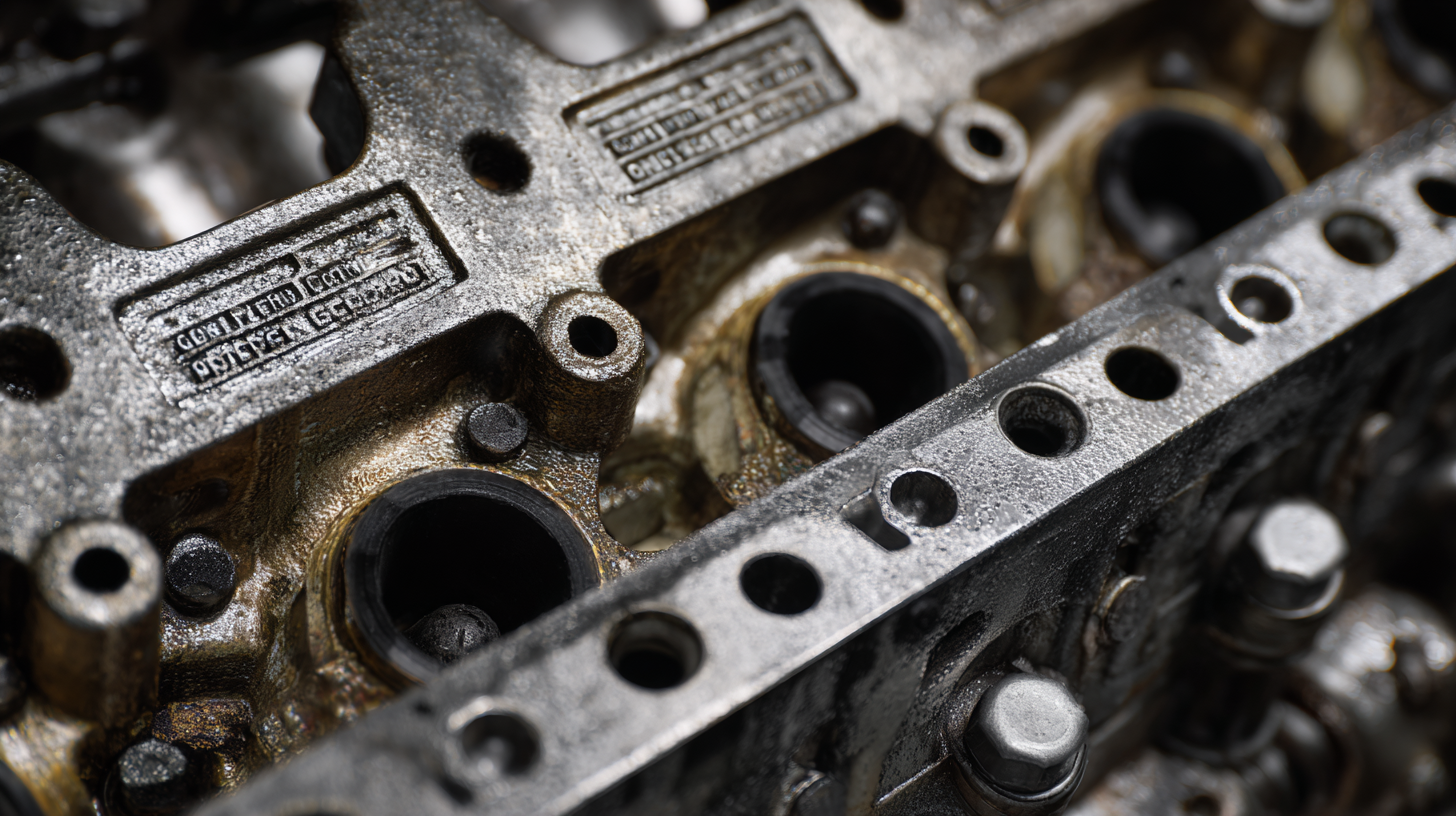

The longevity and performance of your engine cylinder block are crucial elements that every vehicle owner should prioritize. Maintenance plays a vital role in extending the lifespan of this essential component, and one effective strategy involves managing engine heat. Heat soak can severely damage engine parts when the vehicle is parked, causing corrosion and other degradation issues. Implementing proper cooling strategies, such as using a high-performance coolant, can help mitigate these risks and ensure the engine operates at optimal temperatures.

In addition to heat management, regular oil maintenance is equally important. Using oil supplements can enhance engine performance by reducing friction, improving lubrication, and cleaning internal components. Research indicates that vehicles with well-maintained oil systems experience less wear and tear, ultimately leading to longer-lasting engine parts. Considering the rising interest in maintaining automobiles due to supply shortages, these maintenance practices can save both time and money in the long run.