+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

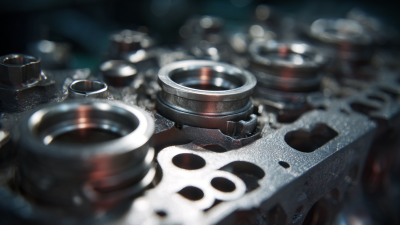

The reliability of your vehicle heavily depends on its engine's components, and one critical part is the Cylinder Head Gasket. This often-overlooked component plays an essential role in sealing the engine's cylinders, preventing coolant and oil from mixing, and maintaining optimal pressure. However, over time, factors such as overheating, wear and tear, or manufacturing defects can lead to a blown Cylinder Head Gasket. Recognizing the signs of this issue is crucial, as ignoring them can lead to severe engine damage and costly repairs.

In this article, we will explore the top signs that indicate your Cylinder Head Gasket may be compromised. From unexplained overheating to milky oil, these symptoms can alert you to potential problems before they escalate. Understanding these warning signs not only empowers you as a vehicle owner but also highlights the importance of timely maintenance and repairs.

Furthermore, we will delve into effective solutions for addressing a blown Cylinder Head Gasket, helping you navigate the repair process confidently. By staying informed and proactive, you can ensure your engine operates efficiently and avoid unnecessary headaches on the road.

A blown cylinder head gasket can lead to significant engine issues, making it crucial for vehicle owners to recognize the warning signs early. One of the most noticeable indicators is the presence of white smoke emanating from the exhaust. This occurs when coolant enters the combustion chamber due to a compromised seal, resulting in steam being expelled along with exhaust gases. Additionally, if you observe an unusual rise in engine temperature, it may signal that the head gasket is failing, as a leak can disrupt proper coolant flow and lead to overheating.

Another symptom to watch for is the presence of that sweet-smelling coolant or oil in places where it shouldn’t be, often pooling under the vehicle or around the engine compartment. You may also notice a milky substance on the oil cap or dipstick, indicating that oil and coolant are mixing.

Finally, paying attention to the engine’s performance is crucial; any signs of misfiring or loss of power can be a red flag, suggesting that the combustion process is being affected by a blown head gasket. Recognizing these signs early can help prevent more extensive damage and costly repairs in the long run.

The failure of a cylinder head gasket can be attributed to several common causes, which, if identified early, can save considerable time and money in repairs. One primary culprit is overheating. When an engine runs at excessively high temperatures, it can cause the head gasket to warp or crack, leading to a loss of integrity. This can occur due to a malfunctioning cooling system, such as a faulty water pump, low coolant levels, or a clogged radiator, which prevents the proper circulation of coolant.

Another significant factor in cylinder head gasket failure is the use of improper installation techniques. When a gasket is replaced, it is crucial to ensure that the surfaces are clean, flat, and properly torqued according to manufacturer specifications. Failure to adhere to these guidelines can result in uneven pressure distribution, potentially causing the gasket to fail prematurely. Additionally, using low-quality materials can also contribute to faster deterioration, especially under the demanding conditions within an engine. Regular maintenance and timely inspections can help mitigate these risks and prolong the life of the head gasket.

Diagnosing a blown cylinder head gasket is crucial for addressing engine issues before they escalate. Begin by checking your engine for signs of coolant leakage. A visible puddle under the engine or white smoke from the exhaust can indicate that coolant is entering the combustion chamber, suggesting a potential gasket failure. Additionally, monitor your engine temperature closely; if it frequently overheats, it might be a sign that the gasket is not sealing properly, impacting coolant flow.

Another vital step in diagnosing a blown gasket is to perform a compression test. This involves using a compression gauge to measure the pressure in each cylinder. If you notice a significant drop in pressure in one or more cylinders compared to the others, this discrepancy can imply a breach in the gasket. Another effective method is checking for exhaust gases in the coolant using a chemical test kit. If combustion gases are present, it further confirms the likelihood of a blown head gasket. By systematically assessing these signs, you can pinpoint issues related to a damaged gasket and take the necessary steps for repair.

| Sign | Description | Diagnosis Steps | Fix |

|---|---|---|---|

| Overheating | Engine temperature rises above normal. | Check coolant levels and look for leaks. | Replace gasket and check for other issues. |

| White Smoke | Thick, white smoke from the exhaust. | Inspect exhaust for smoke while the engine runs. | Replace the cylinder head gasket. |

| Oil Contamination | Milky substance on the oil dipstick. | Check the oil color and consistency. | Flush the engine and replace the gasket. |

| Loss of Power | Decreased engine performance during acceleration. | Conduct a compression test on cylinders. | Repair or replace the affected gasket. |

| Bubbles in Radiator | Bubbles or foam visible in the radiator. | Observe radiator fluid when engine is running. | Replace the cylinder head gasket. |

A blown cylinder head gasket is a common issue in many vehicles, leading to engine overheating and significant damage if not addressed promptly. Fortunately, there are effective repair methods available. The first step is often to identify the problem through a pressure test; this can reveal leaks that indicate a blown gasket.

Once diagnosed, the most reliable repair is to replace the gasket entirely. The process involves disassembling the engine's upper section and carefully removing the old gasket. It’s crucial to clean the surfaces thoroughly to ensure a proper seal, as any residue can lead to future failures.

Another alternative is to use a chemical sealant that is designed to seal minor leaks. These products can be convenient for temporary fixes but should not be viewed as a long-term solution. According to industry reports, about 60% of these sealants fail to hold up under high-pressure conditions, making it vital for car owners to monitor their engines closely even after application.

Tips: Always consult a professional before attempting any repairs, as they can provide insights based on a thorough inspection. Additionally, regular maintenance checks can help catch potential issues before they escalate, reducing the risk of having to deal with a blown head gasket. Finally, using high-quality engine oil can help maintain optimal engine temperature, further preventing gasket failure.

Preventing future gasket issues is crucial for vehicle longevity and performance. According to the Automotive Industry Association, approximately 15% of engines suffer from blown head gaskets due to overheating and wear over time. To mitigate this risk, regular maintenance checks are essential. Keeping the cooling system in good condition, ensuring the oil is clean, and monitoring engine temperatures can significantly reduce the likelihood of gasket failure.

**Tips:** Always check the coolant level and quality before embarking on long trips, as running an engine low on coolant can cause severe damage. Furthermore, consider using high-quality coolant that complies with your vehicle's specifications, as it can provide better thermal protection.

Another effective preventive measure is to maintain proper torque specifications during head bolt tightening. According to industry reports, improper head bolt tension can lead to uneven distribution of pressure and increase the risk of gasket failure. Regularly inspecting and replacing worn or damaged hoses and belts also helps maintain optimal engine temperature, reducing the chances of overheating and ultimately preventing head gasket issues.

**Tips:** Invest in a reliable thermometer to monitor engine temperatures closely and address any rising heat concerns immediately. It’s also wise to adopt a routine inspection schedule every 30,000 miles or as recommended, which can help catch potential problems before they escalate.