+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

In the construction and demolition industries, the breaking hammer, commonly known for its powerful impact and precision, plays an essential role in facilitating various tasks. John Thompson, a renowned expert in hydraulic tools, asserts, "The breaking hammer revolutionizes the way we approach tough materials, combining efficiency with unmatched force." As we delve deeper into the functions and advantages of the breaking hammer, it becomes evident that this tool is not just a piece of equipment but a transformative asset in the field.

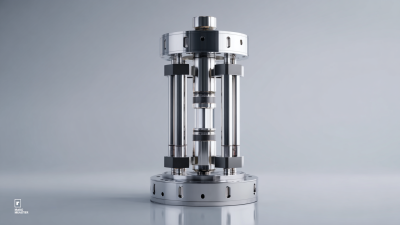

A breaking hammer, often utilized in construction and demolition, is a powerful tool designed to fracture hard materials such as concrete and stone. Understanding the mechanics of a breaking hammer involves recognizing its components and the way they interact to deliver high-impact force. Typically powered by compressed air, electricity, or hydraulic systems, these hammers feature a striking mechanism that transfers energy rapidly to the chisel attachment, enabling it to penetrate and break apart tough structures.

The operation of a breaking hammer hinges on the kinetic energy generated from the hammer's weight coupled with the stroke length. As the hammer strikes the surface, it converts kinetic energy into deformation, facilitating the breaking process. The tool's efficiency is significantly influenced by factors such as impact frequency, strike force, and the design of the chisel. By mastering these mechanics, operators can optimize their use of breaking hammers, leading to enhanced productivity and greater effectiveness in their demolition tasks.

| Dimension | Details |

|---|---|

| Type of Breaking Hammer | Hydraulic, Pneumatic, Electric |

| Common Uses | Concrete demolition, road work, excavation |

| Benefits | Efficiency, power, reduced manual labor, precision |

| Weight Range | 50 lbs to 1000 lbs |

| Operating Pressure (Hydraulic) | 1500 psi to 3000 psi |

| Applications in Industries | Construction, Mining, Demolition |

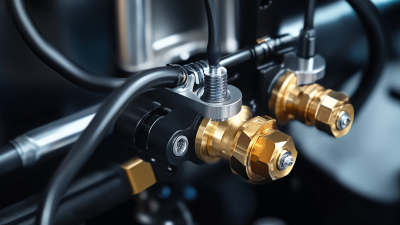

| Maintenance Tips | Regular inspections, proper lubrication, checking seals |

| Operator Safety Gear | Helmets, goggles, gloves, ear protection |

Breaking hammers, or hydraulic hammers, are powerful tools widely utilized across various industries for their efficiency and precision in demolition and construction projects. One of the key applications of breaking hammers can be found in the construction sector, where they are essential for breaking concrete and asphalt. According to a 2021 market analysis by GlobalData, the global construction industry is projected to grow by about 5% annually, which underscores the increasing demand for effective demolition equipment like breaking hammers.

In the mining industry, breaking hammers facilitate the extraction of minerals by breaking up rock formations efficiently. The International Council on Mining and Metals reported that the increasing demand for minerals necessitated the use of advanced machinery, including hydraulic hammers, to optimize performance and reduce operational costs. Additionally, breaking hammers are essential in the recycling sector, where they are employed to dismantle old structures and efficiently separate materials for reuse, contributing to sustainability efforts. The versatility and significant benefits of breaking hammers make them indispensable tools in multiple industrial arenas.

Breaking hammers, often referred to as jackhammers, are essential tools in construction projects, offering distinct advantages that streamline demolition and excavation tasks. One primary benefit of using breaking hammers is their ability to efficiently break through tough materials like concrete and asphalt, significantly reducing the time and effort required for manual demolition. This efficiency not only accelerates project timelines but also helps maintain the flow of work, allowing for a more seamless construction process.

In addition to enhancing productivity, breaking hammers also improve worker safety. Traditional manual tools can exert considerable physical strain on operators, leading to fatigue and potential injuries. However, breaking hammers automate much of the labor, lowering the risk of musculoskeletal injuries and enabling workers to focus more on precision rather than exertion. Furthermore, modern breaking hammers are designed with advanced features such as vibration reduction systems, which lessen the impact on operators, resulting in a safer and more comfortable work environment. Overall, the integration of breaking hammers in construction enhances both efficiency and safety, making them an invaluable asset in the industry.

When selecting a breaking hammer, several critical factors must be taken into account to ensure optimal performance and efficiency. First and foremost, the weight of the hammer plays a pivotal role. According to a recent report by the International Association of Drilling Contractors, breaking hammers with weights ranging from 35 to 60 pounds are favored for medium-duty demolition projects, while heavier options can effectively tackle tough concrete and asphalt.

Another vital consideration is the energy class of the breaking hammer. Research indicates that hammers delivering higher energy per blow (measured in foot-pounds) achieve better results in breaking through tougher materials, significantly reducing labor time. Additionally, the hammer's design and comfort, including handle ergonomics and vibration dampening features, are essential for prolonged use, contributing to worker safety and productivity. Thus, understanding these factors can profoundly impact the effectiveness of a breaking hammer in various industrial applications.

The breaking hammer, a pivotal tool in construction and demolition, is witnessing a transformative evolution as we approach 2025. As per recent industry projections, the global hydraulic breaker market is anticipated to reach a staggering value of $157.49 million by 2025, with further growth expected to elevate this figure to approximately $228.578 million by 2033. This notable increase underscores the growing reliance on advanced hydraulic technologies in various sectors, including mining, construction, and recycling.

Innovations in breaking hammer technology are driving this growth, focusing on improving efficiency, reducing operational noise, and enhancing safety features. As companies invest in research and development, we can expect state-of-the-art designs that optimize performance while minimizing environmental impact. The integration of smart technology and IoT (Internet of Things) capabilities in breaking hammers is also set to revolutionize user experience, providing real-time data analytics and maintenance alerts, ensuring that equipment operates at peak performance. The future of breaking hammers looks promising, all while catering to the ever-evolving needs of the industry.