+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

When embarking on a construction project, choosing the right tools is critical to ensuring efficiency and quality. Among these tools, the "Breaking Hammer" stands out as a vital instrument for demolition and heavy-duty tasks. Understanding the specific requirements of your project is essential, as different types of breaking hammers are designed to address various surfaces and materials. Whether you're breaking concrete, asphalt, or rocks, the selection of the appropriate breaking hammer can greatly influence the speed and effectiveness of your work.

In this guide, we will explore the various factors to consider when selecting a breaking hammer that aligns with your construction needs. From weight and power to ergonomics and safety features, knowing what to look for can make all the difference in your project's success. Additionally, we’ll discuss the importance of selecting a breaking hammer that balances performance and user comfort, ensuring you can complete your tasks with maximum efficiency while minimizing fatigue and risk. As we delve into these considerations, you'll be better equipped to make an informed choice that meets both your operational needs and budgetary constraints.

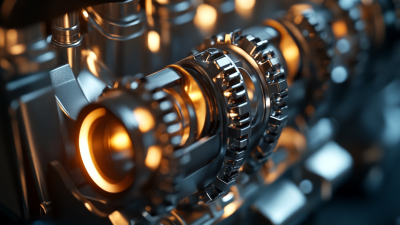

When selecting the right breaking hammer for construction, it is essential to understand the various types available in the market and their specific functions. Demolition hammers, for instance, are designed for breaking up concrete, asphalt, or brick, making them ideal for heavy-duty tasks. These hammers often come with a wide range of attachments, allowing users to switch heads for different applications, such as chiseling or compacting. The power source—whether electric, pneumatic, or hydraulic—also plays a significant role. Electric models are typically lighter and more suited for smaller jobs, while pneumatic and hydraulic options provide more strength for larger projects.

Another critical factor is weight and size. Heavier breaking hammers offer increased impact energy, making them suitable for tougher materials, but they can also be unwieldy for prolonged use. On the other hand, lighter models are easier to handle, reducing fatigue during extended use. Furthermore, consideration should be given to the frequency of use; frequent users might prefer a model that balances power and portability, ensuring efficiency without sacrificing comfort. Understanding these distinctions can significantly impact productivity and safety on the job site, making it vital to choose a breaking hammer that aligns with specific construction needs.

When selecting the right breaking hammer for construction needs, there are several key factors to consider to ensure optimal performance and safety. First, the weight of the hammer plays a crucial role; typically, breaking hammers range from 30 to 90 pounds. A recent study by the Construction Industry Institute found that heavier hammers offer more impact force, which is essential for breaking concrete or asphalt, but can also increase operator fatigue. Therefore, the choice should balance between sufficient weight for effective demolition and manageable usability for extended work periods.

Another significant factor is the power source of the hammer. Pneumatic, electric, and hydraulic models are available, each with its respective advantages. According to data from the National Association of Home Builders, electric hammers have become increasingly popular on job sites due to their portability and ease of use, with nearly 40% of contractors leaning towards this option for residential projects. Conversely, pneumatic hammers are favored for heavy-duty applications, as they provide sustained power and efficiency, particularly in large-scale demolition tasks. Additionally, noise levels, vibration control, and ergonomic design are vital elements that impact worker safety and comfort, making it essential to evaluate these characteristics during the selection process.

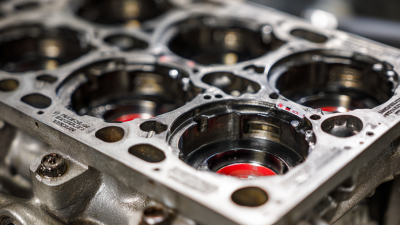

When selecting the right breaking hammer for construction purposes, understanding the power and impact energy it delivers is crucial. Typically measured in joules, impact energy indicates the effectiveness of a hammer in breaking concrete or other tough materials. According to a report from the International Journal of Engineering Research and Applications, hammers with impact energies ranging from 5 to 30 joules are ideal for residential demolition projects, while those exceeding 30 joules are recommended for more demanding industrial applications.

Moreover, it's essential to consider the power output of the hammer, often specified in wattage. Research indicates that breaking hammers with power ratings between 1,200 to 1,800 watts tend to provide optimal performance in various construction settings. These hammers strike a balance between efficiency and manageability, ensuring that operators can handle them comfortably while still delivering considerable force at the point of impact. Choosing a hammer that combines adequate impact energy with the right power rating will ultimately lead to improved productivity and reduced operator fatigue on the job site.

When selecting a breaking hammer for construction projects, weight and portability are critical factors to consider. A breaking hammer's weight often correlates with its power; heavier hammers (typically ranging from 30 to 100 pounds) can exert more force and handle tougher materials. However, they can also lead to fatigue if used for extended periods. According to a report by the Construction Equipment Manufacturers Association, optimizing hammer weight can reduce operator fatigue by as much as 30%, improving overall productivity on the job site.

Portability is another essential feature, particularly for projects that require moving the hammer between locations. Many modern breaking hammers come with ergonomic designs that not only distribute weight more effectively but also incorporate features such as rubberized grips and adjustable carrying handles. The same report highlights that portable designs can enhance operational efficiency and safety, allowing workers to maneuver with ease in confined spaces.

Tips: When choosing a breaking hammer, it’s vital to assess the specific needs of your project. For lightweight tasks, consider models under 40 pounds, while for heavy-duty applications, opt for hammers exceeding 60 pounds. Furthermore, ensure that the hammer's weight is manageable for your team to reduce the risk of injury and promote longer work periods.

When using breaking hammers in construction, safety should always be the top priority. These powerful tools can pose significant risks if not handled properly. Firstly, ensure that you’re wearing the appropriate personal protective equipment (PPE), including safety goggles, gloves, and steel-toed boots. This gear will help protect you from debris and accidental impacts. Additionally, it’s essential to wear ear protection because breaking hammers can produce high noise levels, potentially leading to hearing damage over time.

Another important safety tip is to maintain a firm grip on the hammer at all times. Using both hands to control the tool can help prevent accidental slips and minimize the risk of injury. Additionally, always be aware of your surroundings; make sure the area you are working in is clear of bystanders and obstacles. Before starting, inspect both the breaking hammer and the work area for any hazards such as loose materials or electrical lines. Proper preparation can significantly reduce the likelihood of accidents on the job site.

Lastly, follow the manufacturer's guidelines for operation and maintenance. Understanding how to operate the tool effectively can enhance both safety and efficiency. Regular maintenance checks on the equipment will ensure it remains in good working condition and prevent unexpected breakdowns during use. By adhering to these best practices, you can maximize safety and productivity while using breaking hammers on construction projects.