+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

Common Rail technology has transformed modern engines. Experts agree on its significance. Dr. Emily Carter, a leading authority in automotive engineering, states, "Common Rail systems improve fuel efficiency and reduce emissions." This innovation enhances performance in various vehicles.

The Common Rail system allows for precise fuel injection. It maintains a constant rail pressure to ensure optimal performance. This technology enables multiple injections per cycle. Engines benefit from cleaner combustion and increased power.

However, challenges exist. The complexity of the system can lead to maintenance issues. Drivers must be aware of these potential problems. As technology evolves, we must reflect on how these systems impact our environment and economy. Common Rail systems illustrate both innovation and the need for careful oversight.

Common Rail technology has transformed how modern engines operate.

This system allows for precise control of fuel injection, improving efficiency significantly.

With a common rail, multiple injectors draw from a shared reservoir of pressurized fuel.

This means each cylinder can receive fuel at optimal times.

What makes this technology remarkable is its flexibility.

It adjusts fuel delivery based on speed and load conditions.

This leads to better combustion and lower emissions. However, the complexity of the system can lead to maintenance challenges.

High-pressure pumps and injectors must be kept clean for optimal performance.

If neglected, issues can arise, including reduced efficiency and increased exhaust emissions.

Despite its advancements, there are still areas for improvement.

The reliance on electronic components introduces the potential for failure, which can be costly.

Regular checks are essential to ensure everything functions correctly.

While Common Rail technology represents a leap forward, it is not without its flaws and requires proper care.

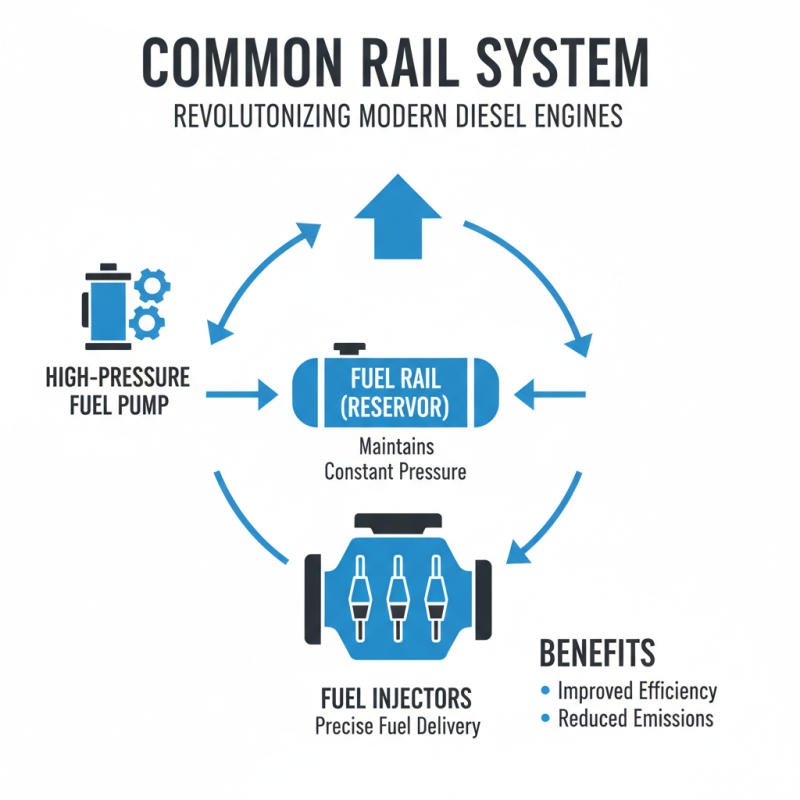

The common rail system revolutionizes modern diesel engines. It enables more precise fuel injection, improving efficiency and reducing emissions. The core components include the fuel rail, injectors, and the high-pressure fuel pump. The rail acts as a reservoir, maintaining pressure for consistent fuel delivery.

Injectors in this system are highly advanced. They can open and close rapidly. This allows multiple injection events per cycle. Research indicates that this flexibility leads to better combustion. This results in up to 20% improved fuel efficiency in some applications. However, maintaining proper pressure is critical. Any failure can lead to performance issues.

The high-pressure pump is crucial for the system's function. It pressurizes the fuel to 1,600 bar or more. This is essential for achieving optimal atomization. Yet, such high pressure can be a challenge. Mechanical wear over time may affect pump performance. Regular maintenance and quality fuel are essential to mitigate this risk. Additionally, the overall complexity raises the cost of repairs.

Common Rail technology is a significant advancement in modern diesel engines. It works by storing high-pressure fuel in a rail system. This allows for precise fuel delivery to each injector. Fuel is injected into the combustion chamber multiple times during each engine cycle. This enhances combustion efficiency. It also reduces emissions and improves overall performance.

In a Common Rail system, the fuel pressure is managed electronically. This means the engine can adjust the timing and quantity of fuel injected. The result is a smoother engine operation. It also results in less noise during combustion. However, some challenges arise. The complexity of the system may lead to maintenance issues. Poor-quality fuel can also cause injector problems. Regular checks are essential to ensure optimal functioning.

This technology's benefits are substantial, yet not without drawbacks. Many users must consider long-term costs. Fuel quality and system durability are critical factors. Understanding Common Rail helps in appreciating its role in diesel engines today. While it delivers remarkable efficiency, the system requires attention and care.

The Common Rail system is an advanced fuel injection technology used in modern diesel engines. The chart above illustrates the different operational pressures of the Common Rail system under various engine conditions: idle, acceleration, cruising, and heavy load. This system allows for precise control of fuel injection timing and quantity, resulting in improved efficiency and reduced emissions.

Common rail fuel injection has transformed the engine landscape. This system allows multiple injections per cycle. By delivering fuel at high pressure, it optimizes combustion. According to a study by the Society of Automotive Engineers, vehicles with common rail systems can improve fuel efficiency by up to 20%. This efficiency contributes to lower CO2 emissions, making it an attractive option.

One prominent advantage is better performance. Engines equipped with common rail systems deliver smoother operation. Research indicates these engines experience less noise and vibration. Drivers enjoy a more pleasant experience overall. However, installation costs can be high, leading to hesitance among manufacturers and consumers alike.

Additionally, common rail systems can lead to increased wear over time. Fuel contaminants can affect injector performance. Regular maintenance becomes critical for sustained efficiency. This means user awareness is essential, but many overlook it. The trade-off between performance and upkeep poses a challenge. Balancing these factors is crucial for long-term satisfaction.

The common rail system has revolutionized fuel injection in modern engines. With advancements in technology, future trends are shaping its evolution. One major trend is the miniaturization of components. Smaller injectors can enhance performance and reduce emissions. This leads to improved fuel efficiency, which is becoming increasingly important.

Another crucial development is the integration of electronic controls. More precise management of fuel injection can lead to smoother engine operation. It allows for real-time adjustments based on driving conditions. However, this added complexity poses challenges in terms of reliability and maintenance. As systems become more digital, issues with comfort in diagnostics may arise.

Additionally, alternative fuels are gaining traction. Common rail systems may adapt to accommodate biodiesel or hydrogen blends. This shift can help meet environmental regulations. Yet, compatibility with existing setups remains uncertain. Will the technology really keep pace with changing fuel trends? The answer requires ongoing research and development. There is still much to explore in the future of common rail systems.

| Dimension | Standard Values | Future Trends |

|---|---|---|

| Pressure for Injection | 1600 - 2000 bar | Up to 2500 bar |

| Injector Type | Solenoid Injectors | Piezoelectric Injectors |

| Fuel Efficiency | 20-25% Better | Enhancements over 30% |

| Emission Standards | EURO 6 | EURO 7 Compliance |

| Common Rail Material | Steel | Lightweight Alloys |