+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

The 2025 China Import and Export Fair, also known as the Canton Fair, will serve as a pivotal platform for showcasing groundbreaking advancements in numerous industries, particularly in automotive components like the Crankshaft Bearing. According to a recent market analysis from Allied Market Research, the global bearing market is projected to reach approximately $105.7 billion by 2025, driven by the rising demand for high-performance and durable components in the automotive sector.

Crankshaft Bearings, essential for the smooth operation of internal combustion engines, are increasingly being engineered using advanced materials and innovative technologies to enhance efficiency and longevity. This year's fair will highlight significant innovations in Crankshaft Bearing designs, including the integration of smart technologies and lightweight materials, addressing the industry's need for sustainable and high-performance solutions.

As participants from around the world converge at this esteemed event, the future of Crankshaft Bearing technology will be at the forefront of discussions, heralding a new era for automotive engineering.

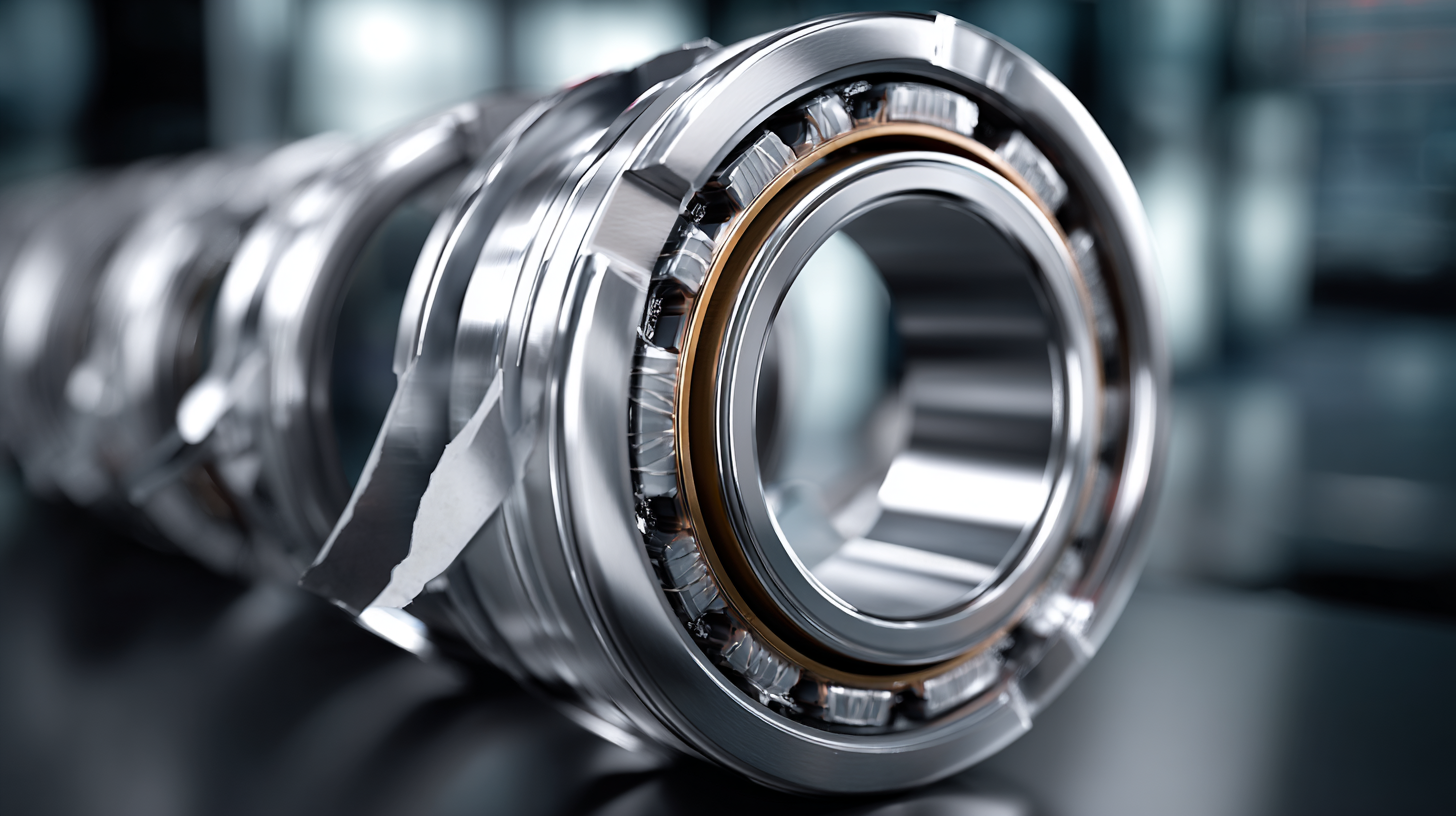

The 2025 China Import and Export Fair presents a pivotal opportunity to delve into the latest innovations in crankshaft bearings, particularly focusing on the use of advanced materials. As the automotive industry evolves, there is a significant shift towards lightweight materials aimed at enhancing both performance and efficiency. Recent systematic reviews highlight the emergence of light alloys and high-strength steels as crucial components in the development of next-generation crankshaft bearings. These materials not only contribute to weight reduction but also improve durability and wear resistance, essential for the high-performance demands of modern engines.

Furthermore, the adoption of innovative materials extends beyond just automotive applications; it is reshaping standards across related industries. The integration of advanced composites in crankshaft and gearbox designs exemplifies this trend, reflecting a broader industry movement towards sustainable and efficient engineering solutions. As manufacturers continue to explore these innovations, the ability to enhance engine performance while reducing overall vehicle weight will play a vital role in meeting environmental and economic challenges in the years ahead.

This chart illustrates the trends in the use of innovative materials for crankshaft bearings based on recent market research.

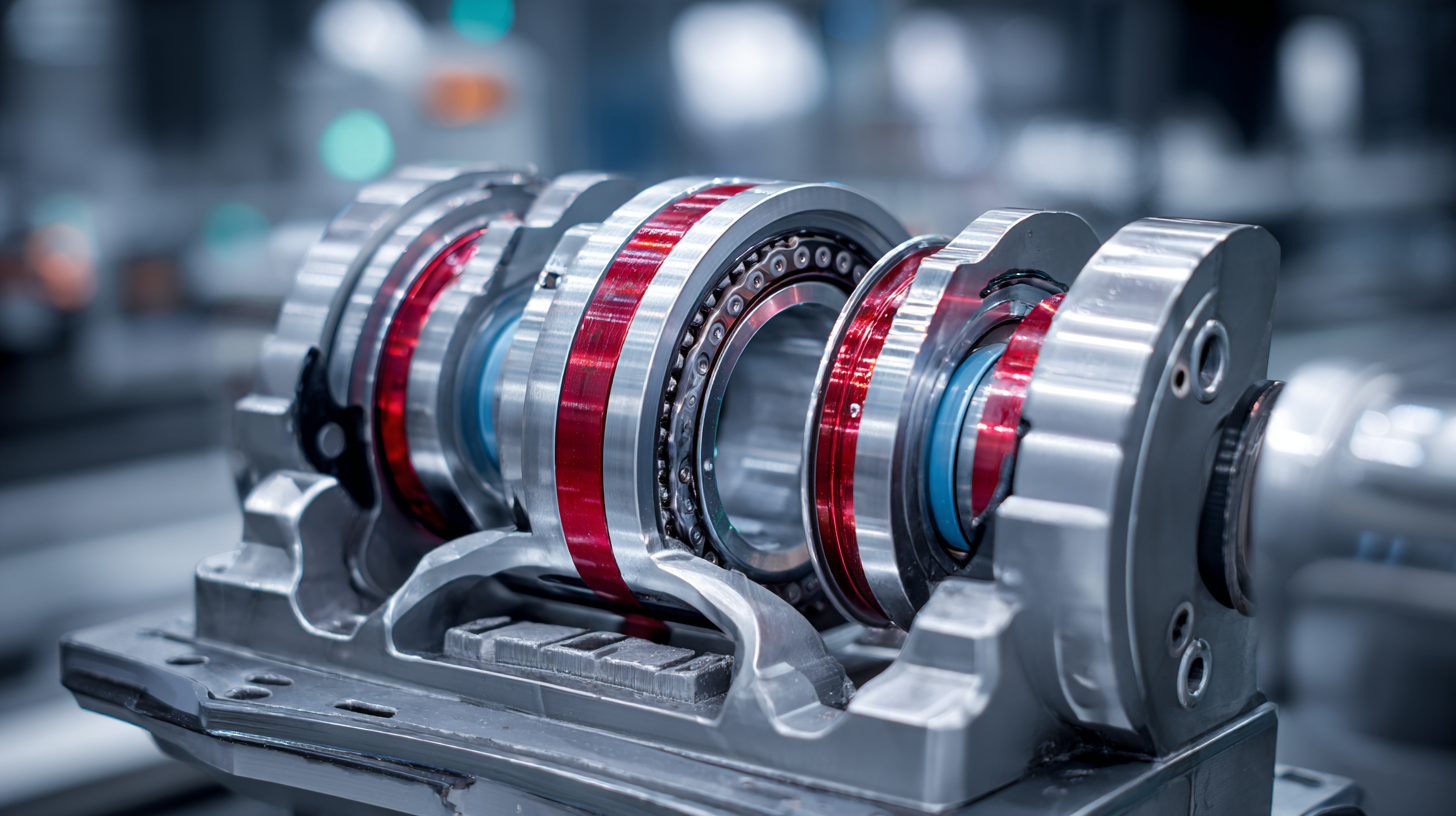

At the 2025 China Import and Export Fair, innovations in crankshaft bearing technologies are set to take center stage, playing a pivotal role in enhancing engine performance. Advanced bearing technologies are crucial to achieving higher efficiency and lower emissions in modern engines. As manufacturers strive to meet stringent environmental regulations, the development of innovative materials and designs in crankshaft bearings can significantly impact overall engine functionality. These advancements aim to reduce friction, improve load distribution, and extend the lifespan of engine components, ultimately leading to more sustainable automotive solutions.

Moreover, the exploration of smart bearing systems equipped with integrated sensors offers a glimpse into the future of engine management. By utilizing real-time data, these systems can optimize performance and facilitate predictive maintenance, thus reducing the risk of engine failures. The fair will showcase not only cutting-edge bearing technologies but also collaborative efforts between manufacturers and research institutions, highlighting the importance of innovation in driving the automotive industry forward.

The synergy between advanced bearing design and engine performance could revolutionize how vehicles operate, marking a significant milestone in automotive engineering.

The 2025 China Import and Export Fair will serve as a pivotal platform to showcase innovations in crankshaft bearing production, particularly focusing on sustainable manufacturing practices. As the automotive industry grapples with the challenges of environmental impact, manufacturers are increasingly turning to eco-friendly materials and production techniques. This shift not only reduces waste but also enhances the overall efficiency of crankshaft bearing components.

Among the notable sustainable practices, additive manufacturing is gaining traction, allowing for the creation of intricate designs with minimal material waste. Additionally, the integration of recycled materials into the production process signifies a commitment to sustainability, showcasing how advanced technologies can be harmoniously aligned with environmental goals. By prioritizing these innovative practices, the industry aims to reduce its carbon footprint while maintaining high performance and durability standards in crankshaft bearings.

| Innovation Type | Description | Sustainability Feature | Impact on Production | Potential Market Reach |

|---|---|---|---|---|

| Eco-Friendly Materials | Utilization of biodegradable composites for bearing manufacturing. | Reduces plastic waste and improves recyclability. | Lower costs in waste management and compliance. | Global market of eco-conscious manufacturers. |

| Advanced Lubrication Technology | Innovative lubricants that require less frequent application. | Decreases resource consumption and maintenance needs. | Increases operational efficiency and lowers production downtimes. | Automotive and industrial machinery sectors. |

| 3D Printing Techniques | Using additive manufacturing for custom bearing production. | Minimizes material waste during production. | Enables quick prototyping and reduced lead times. | High-value niche markets and specialized applications. |

| Smart Bearing Monitoring | Integration of IoT technology for real-time monitoring. | Enhances performance tracking and predictive maintenance. | Reduces failures and extends bearing life cycle. | Wide industrial applications, especially in heavy machinery. |

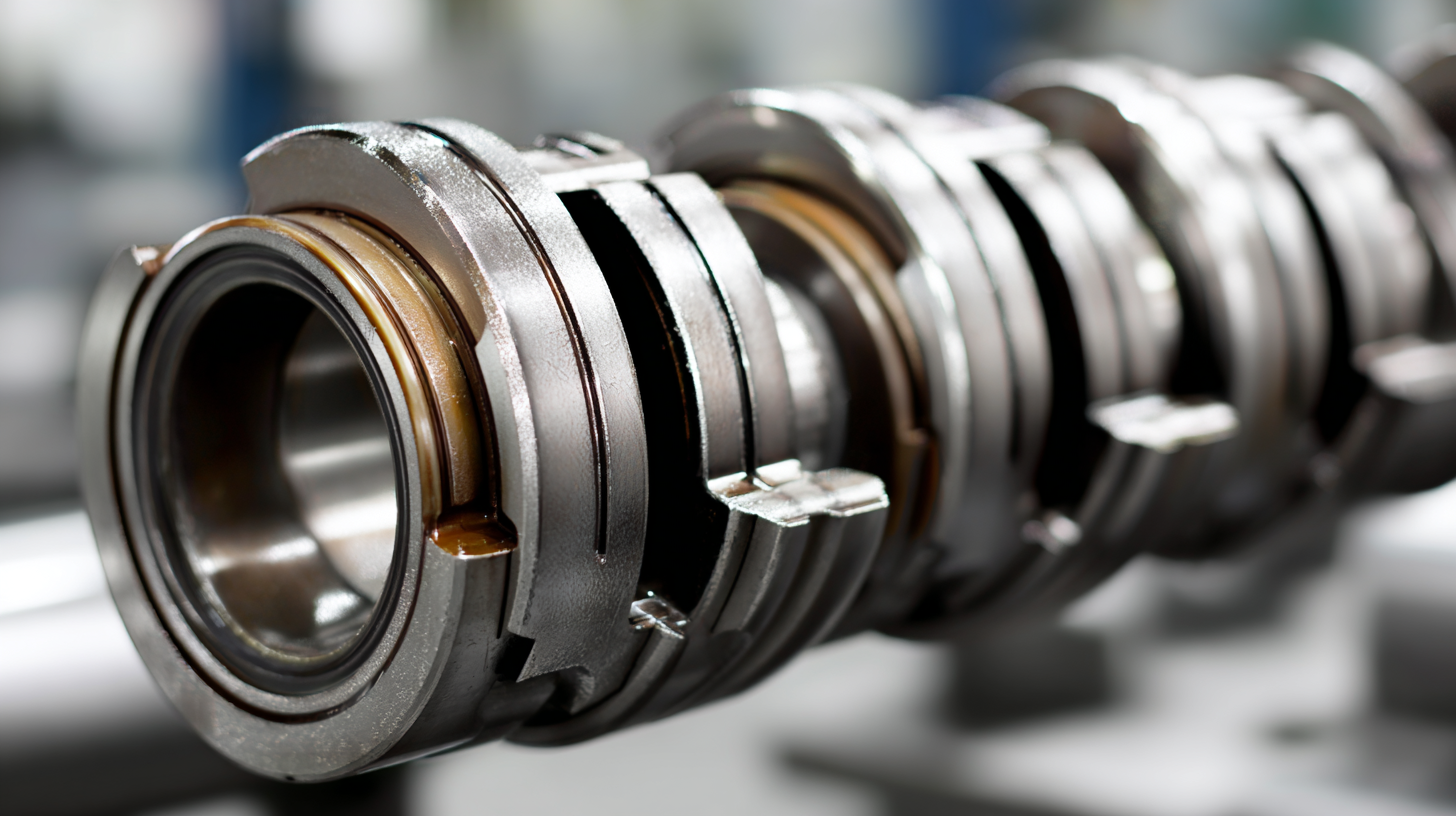

The design and application of crankshaft bearings face several challenges that require innovative solutions. One primary issue is the high stress and temperatures these components endure in modern engines. As engines become more powerful and efficient, the demands on bearings increase significantly, leading to potential failure if materials and designs are not optimized. To address this, manufacturers are exploring advanced materials such as composites and specialized coatings that enhance durability and reduce friction, thus extending the lifespan of these critical components.

Another challenge lies in the compatibility of crankshaft bearings with the increasingly complex engine designs. The integration of hybrid and electric vehicle technologies introduces unique requirements for vibration control and noise reduction. Engineers are focusing on precision manufacturing techniques that ensure a perfect fit and alignment, minimizing wear and enhancing performance. Collaborative efforts among industry experts at the 2025 China Import and Export Fair highlight innovative approaches, such as the use of simulation software for better predictive analysis during the design phase, ensuring that bearings can withstand the evolving demands of modern automotive applications.

The automotive industry is witnessing a significant shift in crankshaft bearing innovations, particularly as manufacturers adapt to rising performance demands. Future prospects indicate that the engine bearings market, which includes main bearings, connecting rod bearings, and others, is expected to flourish. According to industry analysis, the market size is projected to expand as automotive sales continue to rise, driving the need for more advanced forged components that can withstand higher workloads demanded by modern engines.

Innovative designs are emerging to address the challenges posed by outrageous boost levels in engine performance. As engine builders experiment with new applications, manufacturers are required to enhance the reliability and performance of crankshaft bearings. A key focus is the development of lightweight materials and advanced manufacturing technologies, which are critical for optimizing engine efficiency and durability. Reports suggest a growing interest in synthetic oil technologies that complement these innovations, ensuring that crankshaft bearings perform consistently under varying conditions. This convergence of advancements is likely to reshape the landscape of automotive engineering, paving the way for more efficient and durable vehicles in the future.