+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

As we move towards 2025, the world is witnessing significant advancements in electric pump technology that are poised to reshape global supply chains. Electric pumps, known for their efficiency and sustainability, are becoming increasingly integral in various industries, from agriculture to manufacturing. These innovations not only enhance operational efficiency but also contribute to reducing carbon footprints, aligning with the growing demand for sustainable practices. Moreover, the integration of smart technologies in electric pumps is revolutionizing how industries manage water and fluid transfer processes. This blog will explore the emerging trends in electric pump technology, examining their implications not just for operational performance but also for logistics, supply chain dynamics, and environmental sustainability. As businesses prepare to adapt to these changes, understanding the impact of electric pumps on global supply chains will be crucial for maintaining competitiveness in an evolving market landscape.

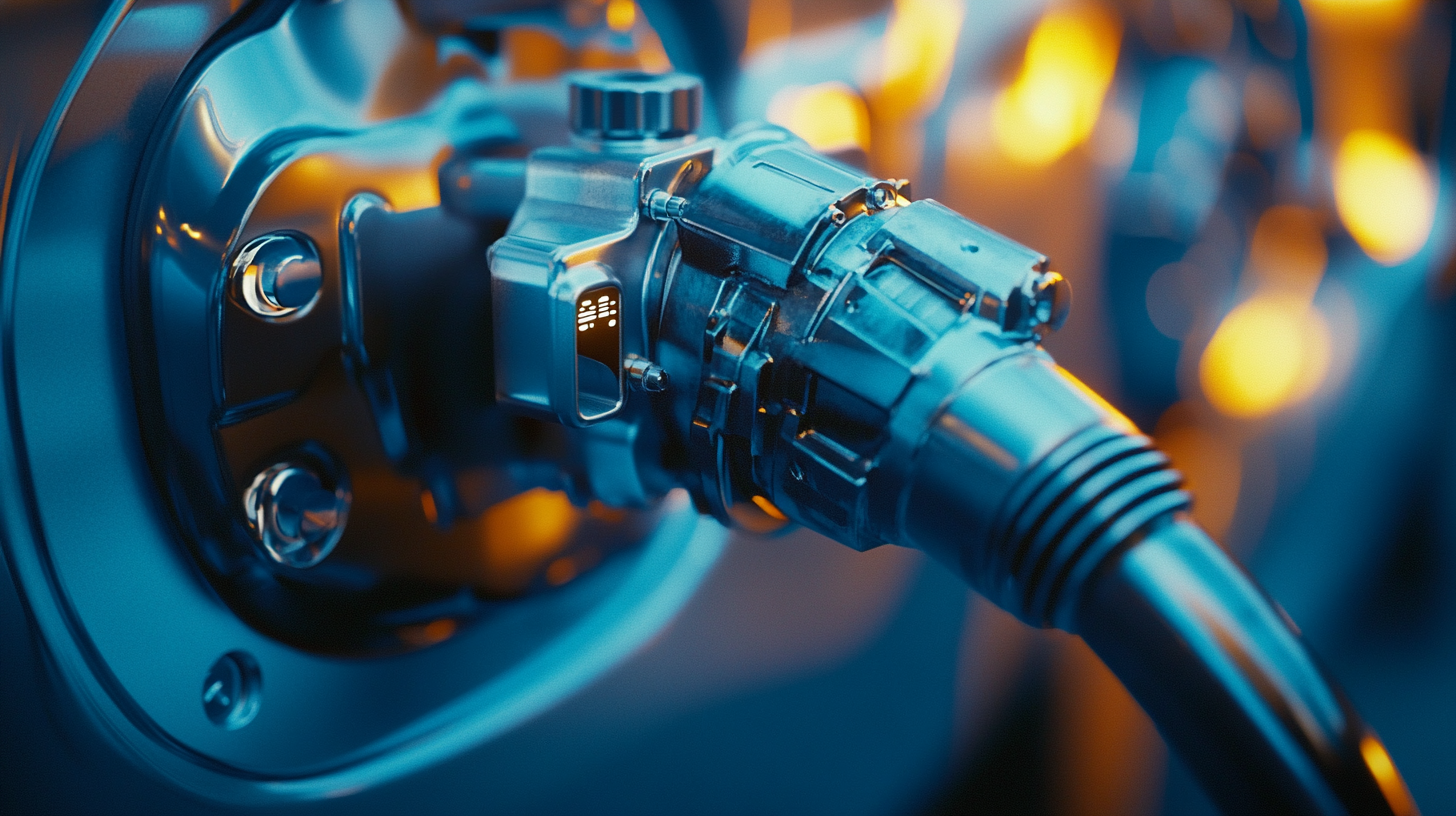

The electric pump technology landscape is rapidly evolving, with significant advancements anticipated for 2025. One of the key trends includes the integration of smart technologies, allowing pumps to utilize IoT connectivity for real-time monitoring and efficient operation. This advancement not only enhances the accuracy of fluid delivery but also enables predictive maintenance, minimizing downtime and ensuring consistent performance. As facilities increasingly seek to optimize their processes, the ability to remotely manage and troubleshoot electric pumps will be crucial.

Moreover, breakthroughs in materials and design are set to drive efficiency to new heights. Manufacturers are exploring lightweight, durable materials that reduce energy consumption while improving the longevity of pumps. Enhanced aerodynamic designs are also being developed to decrease friction losses and increase flow rates. These innovations will not only lower operating costs but also reduce the environmental impact associated with traditional pumping systems, aligning with global initiatives for sustainability. As the industry gears up for 2025, these advancements will undoubtedly reshape the dynamics of supply chains, affecting everything from production techniques to end-user satisfaction.

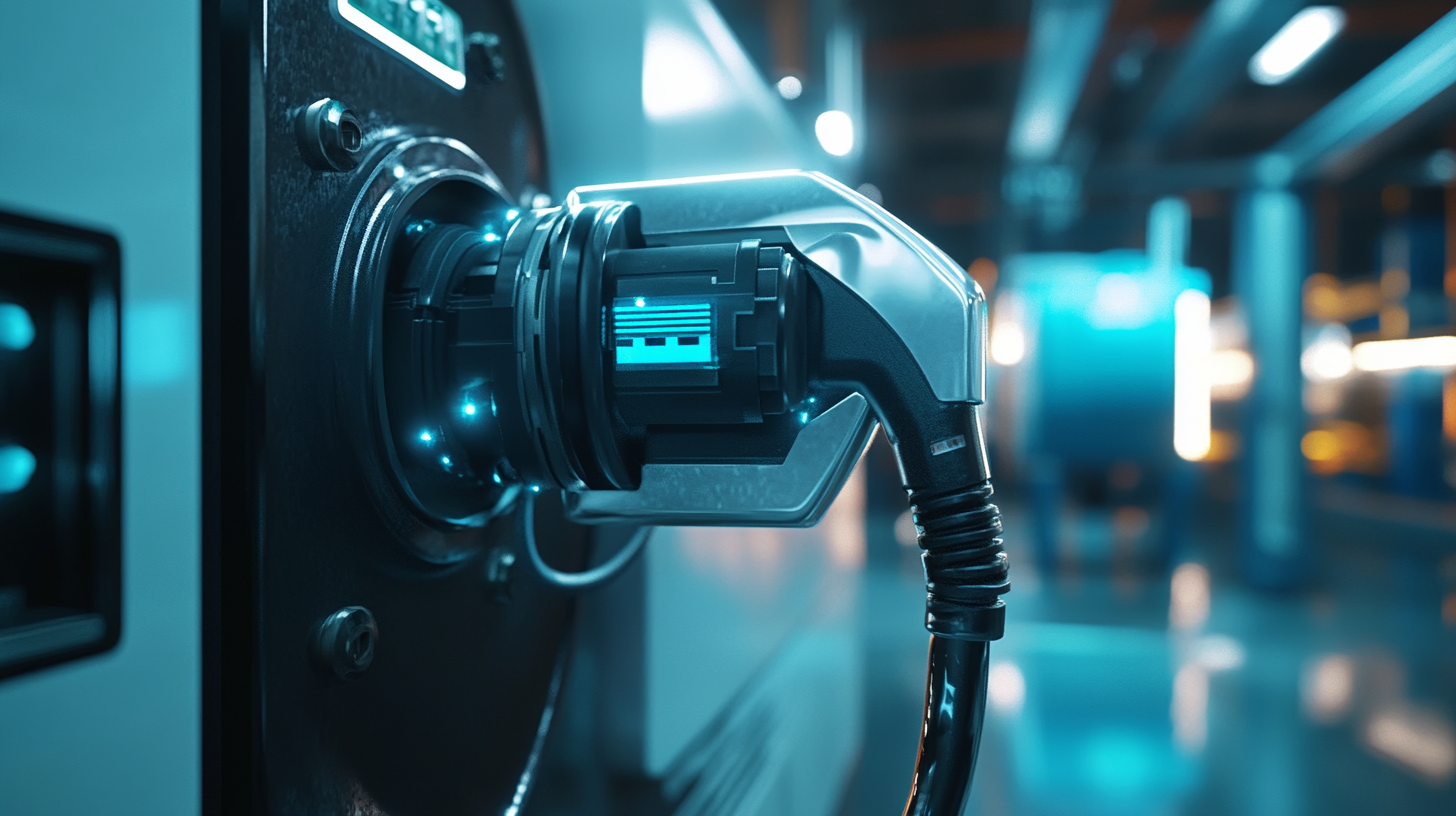

As we advance toward 2025, the integration of Internet of Things (IoT) and smart technologies in electric pump systems presents a transformative shift in operational efficiencies and supply chain dynamics. According to a report by MarketsandMarkets, the global IoT in the pump market is projected to reach $3.5 billion by 2025, illustrating a compound annual growth rate (CAGR) of over 25%. This growth is driven by the increasing demand for real-time monitoring and predictive maintenance capabilities in various industries, including water and wastewater management, agriculture, and oil and gas.

Smart technologies, powered by IoT connectivity, enhance the electric pump systems through data analytics and automation. By leveraging sensors and cloud computing, operators can monitor pump performance, detect anomalies, and preemptively address issues, significantly reducing downtime. A report from the International Energy Agency (IEA) indicates that smart pumps can improve energy efficiency by 30% compared to conventional systems. This not only optimizes operational expenses but also enhances sustainability initiatives, a growing concern in today's supply chains.

Furthermore, the ripple effect of these advancements impacts global supply chains by improving logistics and inventory management. Enhanced predictability in pump performance helps suppliers to streamline their manufacturing processes and reduce lead times. The sync between IoT-driven insights and supply chain operations fosters a more responsive and agile framework, meeting the challenges posed by fluctuating market demands and helping businesses maintain a competitive edge.

The sustainability trends driving electric pump innovation are increasingly reshaping global supply chains, as businesses strive to meet stringent environmental regulations and consumer demand for greener technologies. According to a report by Grand View Research, the global electric pump market is projected to reach $53 billion by 2025, growing at a compound annual growth rate (CAGR) of 4.3%. This growth is largely fueled by the need for energy-efficient solutions that minimize carbon footprints during production and distribution processes.

One of the most significant advancements in electric pump technology is the integration of IoT and smart sensors, which allows for real-time monitoring and optimization of pump performance. A study by MarketsandMarkets highlights that the IoT in the manufacturing sector could lead to a reduction in energy consumption by up to 30%. By utilizing advanced analytics, companies can optimize their supply chains, forecast demand better, and reduce waste, thereby enhancing overall sustainability.

Moreover, the shift towards renewable energy sources is also propelling the innovation of electric pumps. According to a report from Allied Market Research, the use of electric pumps powered by solar and wind energy is expected to rise by over 25% in the next few years. This transition not only helps in achieving sustainability goals but also reduces dependency on fossil fuels, promoting a cleaner environment. As businesses adapt to these trends, electric pumps will play a crucial role in fostering sustainable practices throughout their supply chains.

As we look toward 2025, the electric pump manufacturing sector is poised for significant transformation, largely influenced by evolving regulatory changes. The Clean Power 2030 Action Plan in the UK illustrates a strategic pivot towards cleaner electricity, which is likely to shape production standards and operational practices within the industry. Manufacturers are expected to enhance their digital and data foundations to comply with new regulations while also addressing the persistent skills gap in the workforce. According to the 2025 Manufacturing Industry Outlook report, these investments in technology and skills will be critical for fostering innovation and maintaining competitive advantage.

Furthermore, the rising demand for sustainable solutions is driving electric pump manufacturers to adapt their distribution strategies. With insights from Deloitte's Renewable Energy Industry Outlook, it is evident that sectors leveraging clean technology are experiencing invigorated growth, as regulations favoring sustainability are intensifying. As electric pumps play a pivotal role in various applications, from agricultural irrigation to industrial processes, their manufacturing and distribution models will need to be agile and forward-thinking. This shift not only enhances operational efficiencies but also aligns with the broader moves towards decarbonization and sustainable practices.

The landscape of global supply chains for electric pumps is rapidly evolving, driven by technological advancements and the urgent demand for sustainable solutions. One of the significant challenges faced by manufacturers is the need to adapt to the swift pace of innovation while managing cost efficiency. As electric pump technology becomes more sophisticated, companies must invest in new manufacturing processes and raw materials, which can strain supply networks that traditionally emphasize cost over flexibility. Disruptions caused by geopolitical tensions and environmental factors also complicate the sourcing of essential components, necessitating a reevaluation of existing supply chain strategies.

However, these challenges present unique opportunities for growth and reconfiguration in the electric pump sector. The increasing emphasis on energy efficiency and carbon reduction opens avenues for innovative pump designs that utilize smart technology and automation. Companies that embrace these trends can establish themselves as market leaders. Furthermore, collaboration between manufacturers and suppliers is becoming crucial. Developing closer partnerships can enhance transparency and adaptability within supply chains, allowing businesses to respond more effectively to market demands and disruptions. By leveraging technological advancements and fostering a resilient supply chain, the electric pump industry can thrive in the coming years.