+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

In the ever-evolving landscape of the automotive and industrial sectors, the significance of Fuel Control Valves has surged dramatically over the past decade. According to a report by MarketsandMarkets, the global fuel injection systems market, which includes fuel control valves, is projected to reach USD 59.3 billion by 2025, growing at a CAGR of 6.8% from 2020. This growth is driven by the increasing demand for fuel-efficient vehicles and stringent emission regulations worldwide. As manufacturers and buyers alike seek to optimize performance and comply with environmental standards, a comprehensive understanding of Fuel Control Valve solutions becomes essential. This guide aims to equip global buyers with the knowledge necessary to navigate the complexities of fuel control valve selection, addressing everything from technological advancements to supplier evaluation, thus ensuring informed decision-making in this critical component of modern fuel systems.

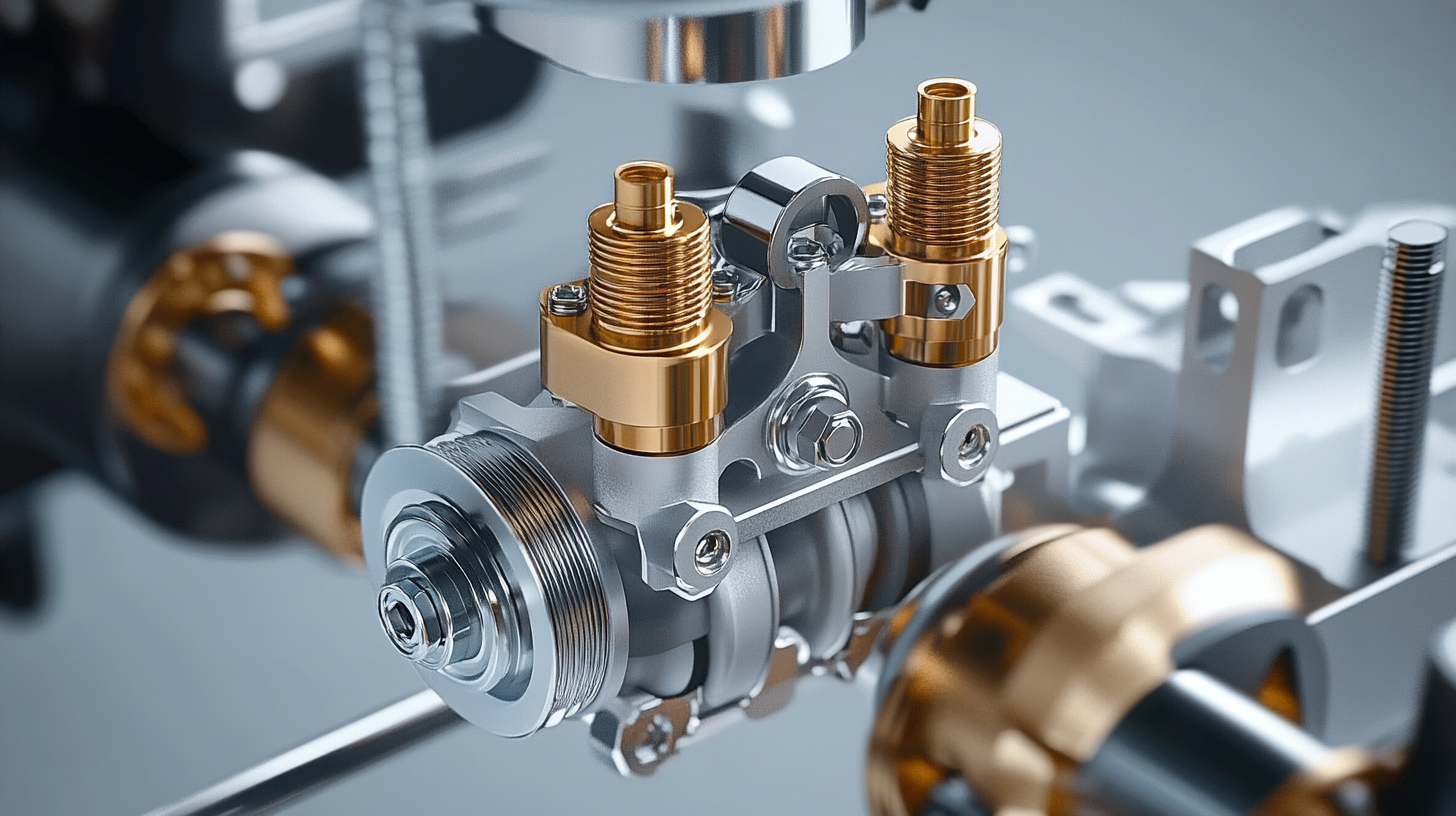

Fuel control valves are essential components in various machinery and vehicles, playing a crucial role in regulating fuel flow and ensuring optimal engine performance. Understanding the different types of fuel control valves is key for buyers looking to enhance their systems. Generally, these valves can be categorized into two main types: electronic and mechanical. Electronic fuel control valves utilize sensors and electronic control units to adjust fuel delivery precisely, making them ideal for modern engines that require accurate fuel management for efficiency and emissions control. On the other hand, mechanical fuel control valves operate on simple principles and are often used in older models or specific applications where cost and reliability are prioritized.

Each type of fuel control valve serves specific functions. For instance, the solenoid-operated valve provides quick and responsive fuel flow adjustment, while the pressure control valve maintains the desired fuel pressure within the system. Understanding these functions is vital for global buyers, as it enables them to choose the right valve based on their operational needs and engine specifications. Furthermore, awareness of how different valves interact with other engine components can help in troubleshooting and optimizing performance, ensuring that machines run smoothly and efficiently.

| Valve Type | Function | Application | Benefits |

|---|---|---|---|

| Solenoid Valve | Controls fuel flow using electrical signals | Automotive, Industrial | Quick response, reliable operation |

| Pneumatic Valve | Regulates fuel flow using compressed air | Maritime, Aerospace | High speed, low maintenance |

| Manual Valve | Operated by hand to control fuel flow | Generators, Tanks | Cost-effective, simple operation |

| Flow Control Valve | Regulates flow rate of fuel | Chemical processing, Refineries | Precise flow control, energy efficiency |

When selecting fuel control valve solutions, several key factors should be taken into account to ensure optimal performance and reliability. Firstly, it is crucial to assess the technical specifications of the valves. Buyers should consider aspects such as pressure ratings, flow capacity, and material compatibility with the fuel being used. These specifications will directly impact the valve's efficiency and lifespan, making it essential to match them with precise operational requirements.

Another vital factor involves the intended application and environmental conditions. Different industries, such as automotive, aviation, or marine, may demand specific features like corrosion resistance or high-temperature capabilities. Understanding the operational environment helps in choosing valves that can withstand conditions such as temperature fluctuations, exposure to chemicals, and other stressors that could degrade performance.

Lastly, it is important to evaluate the supplier's reputation and support services. A reliable supplier not only provides high-quality products but also offers technical support, warranties, and after-sales services. Engaging with trusted manufacturers ensures that buyers can access expert advice and assistance, ultimately leading to informed decisions and an effective fuel control system tailored to their needs.

In the ever-evolving landscape of fuel control valves, key manufacturers play a crucial role in meeting the diverse needs of global buyers. Among the top players in this field is Westport Fuel Systems Inc., known for their innovative hydrogen valve solutions essential for transitioning to cleaner fuel alternatives. The hydrogen valve market is projected to witness significant growth, making Westport a pivotal player alongside other notable manufacturers such as KITZ Corporation, which specializes in high-performance valves for various applications.

Jewellok is also making strides in the sector by expanding its ultra-high purity gas solutions. Their advanced pressure regulators and control valves are specifically designed for semiconductor and biotech applications, highlighting the increasing demand for precision in industries reliant on clean gas technologies. This trend reinforces the necessity for manufacturers to stay ahead by providing sophisticated products tailored to the evolving requirements of end-users.

With the Middle East industrial valve market expected to reach USD 2.7 billion by 2024 and growing at a CAGR of over 6.6% through 2034, the competitive landscape will likely intensify. Manufacturers must not only focus on quality but also on innovation in fuel control valve solutions to capture a larger share of this burgeoning market. The integration of technology and a commitment to sustainable practices will be vital for long-term success in this sector.

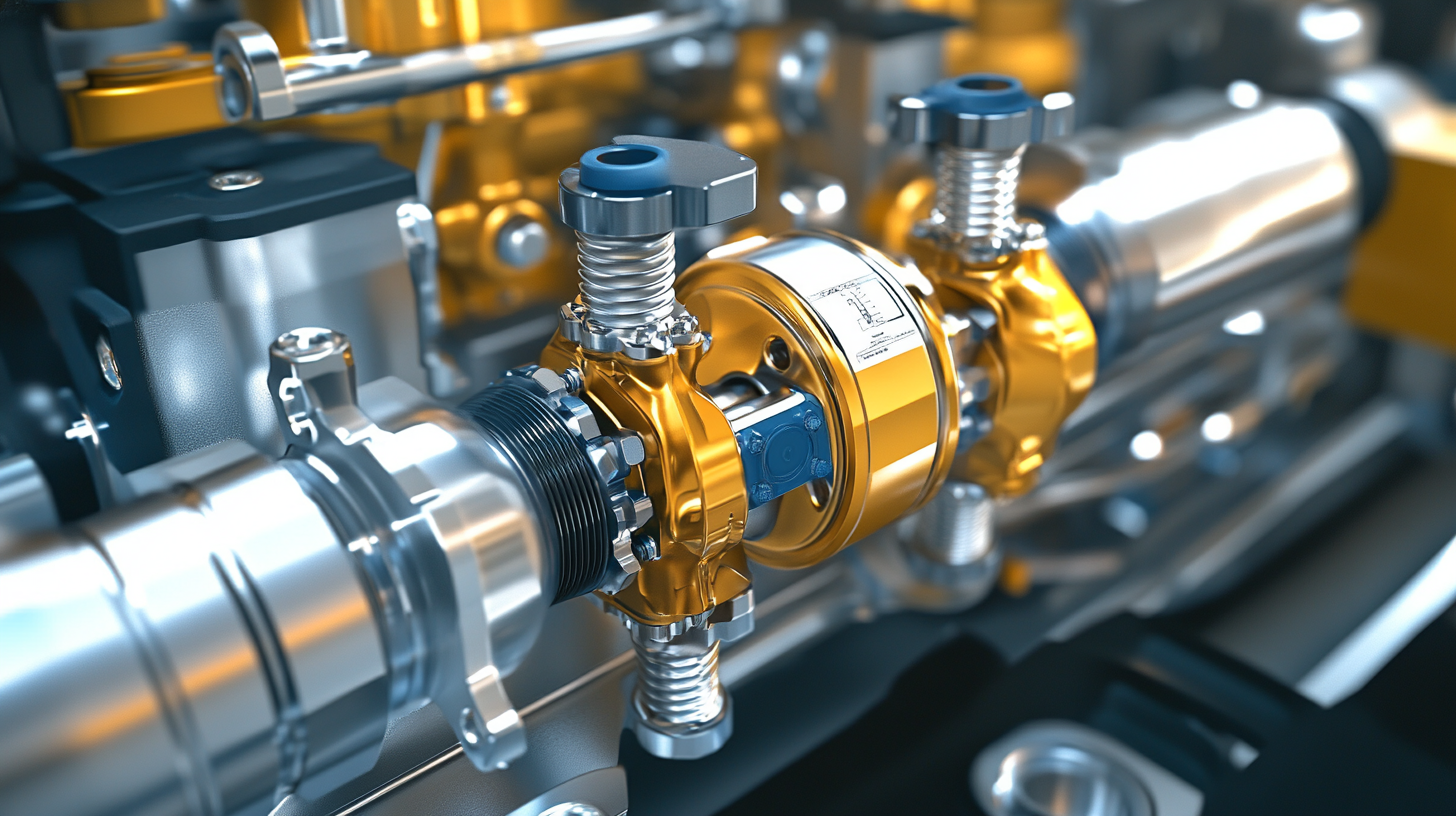

Fuel control valves play a critical role in various industries, from automotive to aerospace and energy production. According to a report by MarketsandMarkets, the global fuel control valve market is expected to reach USD 2.5 billion by 2025, growing at a CAGR of 4.2%. This growth can be attributed to the increasing demand for fuel-efficient systems and the rising need for advanced control technologies in engines.

In the automotive sector, fuel control valves are indispensable for managing fuel injection systems, which directly impact vehicle performance and efficiency. The International Energy Agency states that improving fuel efficiency in transportation could reduce global oil demand by 13 million barrels per day by 2030. Similarly, in the aerospace industry, the precision offered by fuel control valves ensures optimal engine performance and compliance with rigorous safety standards. The Federal Aviation Administration (FAA) emphasizes that effective fuel management contributes significantly to reducing operational costs and enhancing flight safety.

Moreover, the energy production sector heavily relies on fuel control valves for processes like combustion control in power plants. The Energy Information Administration (EIA) indicates that advancements in valve technologies could help optimize emissions control and improve the overall efficiency of energy generation. As industries continue to innovate, the demand for reliable and effective fuel control valve solutions will only increase, highlighting their crucial role in today's economy.

The technological landscape of fuel control valves is rapidly evolving, particularly with the integration of hydrogen energy systems. Recent studies reveal that hydrogen has the potential to play a crucial role in transforming the global energy landscape, offering a cleaner alternative that can significantly mitigate climate change impacts. According to industry analysts, the hydrogen market is projected to grow at a compound annual growth rate (CAGR) of over 15% through the next decade, signaling robust demand for innovations in hydrogen valve technologies.

Digital transformation is another key trend shaping the fuel control valve sector. With advancements in smart technologies, manufacturers are now able to integrate IoT capabilities into their valve solutions, enhancing operational efficiency and predictive maintenance. Reports indicate that the digital valve market alone is expected to exceed $3 billion by 2025, driven by the need for better control mechanisms in complex industrial environments. This shift is pushing companies to explore new digital and hydraulic technologies that could redefine traditional valve operations.

Furthermore, the competitive landscape of hydrogen valve technology is becoming increasingly dynamic. Key players in the market are investing heavily in research and development to unveil cutting-edge products that cater to the specific demands of hydrogen applications. An analysis indicates that companies involved in hydrogen valve innovations are likely to see increased market shares as they capitalize on this new energy frontier, reflecting the urgent need for environmentally friendly solutions across various industries.