+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

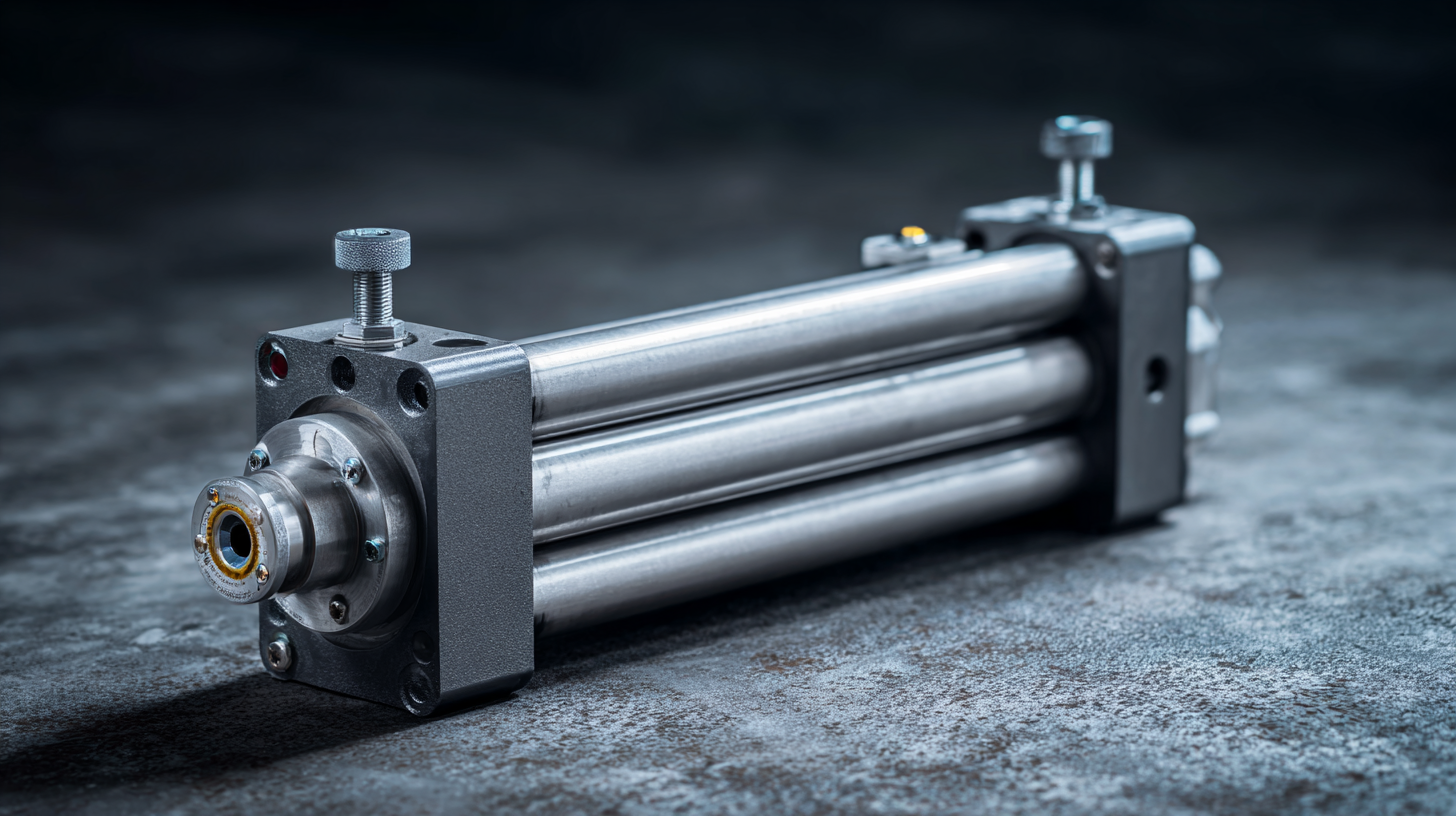

Selecting the right arm cylinder for your industrial applications is a critical decision that can significantly impact productivity and efficiency. Arm cylinders, essential components in various mechanical systems, play a pivotal role in tasks such as lifting, pushing, and pulling materials or equipment. Their design and functionality must align with the specific requirements of the application, including load capacity, stroke length, and mounting options.

Additionally, considerations such as the operating environment, fluid compatibility, and manufacturer reliability are vital to ensure optimal performance and longevity of the arm cylinder. In this guide, we will explore the key factors to consider when choosing the ideal arm cylinder, enabling you to make informed decisions that enhance the effectiveness of your industrial processes.

Additionally, considerations such as the operating environment, fluid compatibility, and manufacturer reliability are vital to ensure optimal performance and longevity of the arm cylinder. In this guide, we will explore the key factors to consider when choosing the ideal arm cylinder, enabling you to make informed decisions that enhance the effectiveness of your industrial processes.

When selecting the right arm cylinder for industrial applications, it's crucial to understand the functionality these components offer in various settings. Arm cylinders play a pivotal role in automating tasks and enhancing precision in manufacturing processes. Their ability to exert force and provide controlled movement makes them ideal for applications such as assembly lines, material handling, and robotic systems. The choice of arm cylinder can significantly impact the efficiency and cost-effectiveness of production schedules.

In environments such as weapons manufacturing, where rapid production and reliability are paramount, the integration of advanced arm cylinders can streamline operations. The use of robotic arms equipped with these cylinders enables systematic inspections and handling of components, reducing the risk of human error. Additionally, as industries strive for lower costs and quicker production timelines, understanding the specifications, such as stroke length and force capacity, becomes essential for selecting the most suitable arm cylinder to meet operational demands. By prioritizing functionality and reliability, manufacturers can ensure that their systems operate smoothly and efficiently.

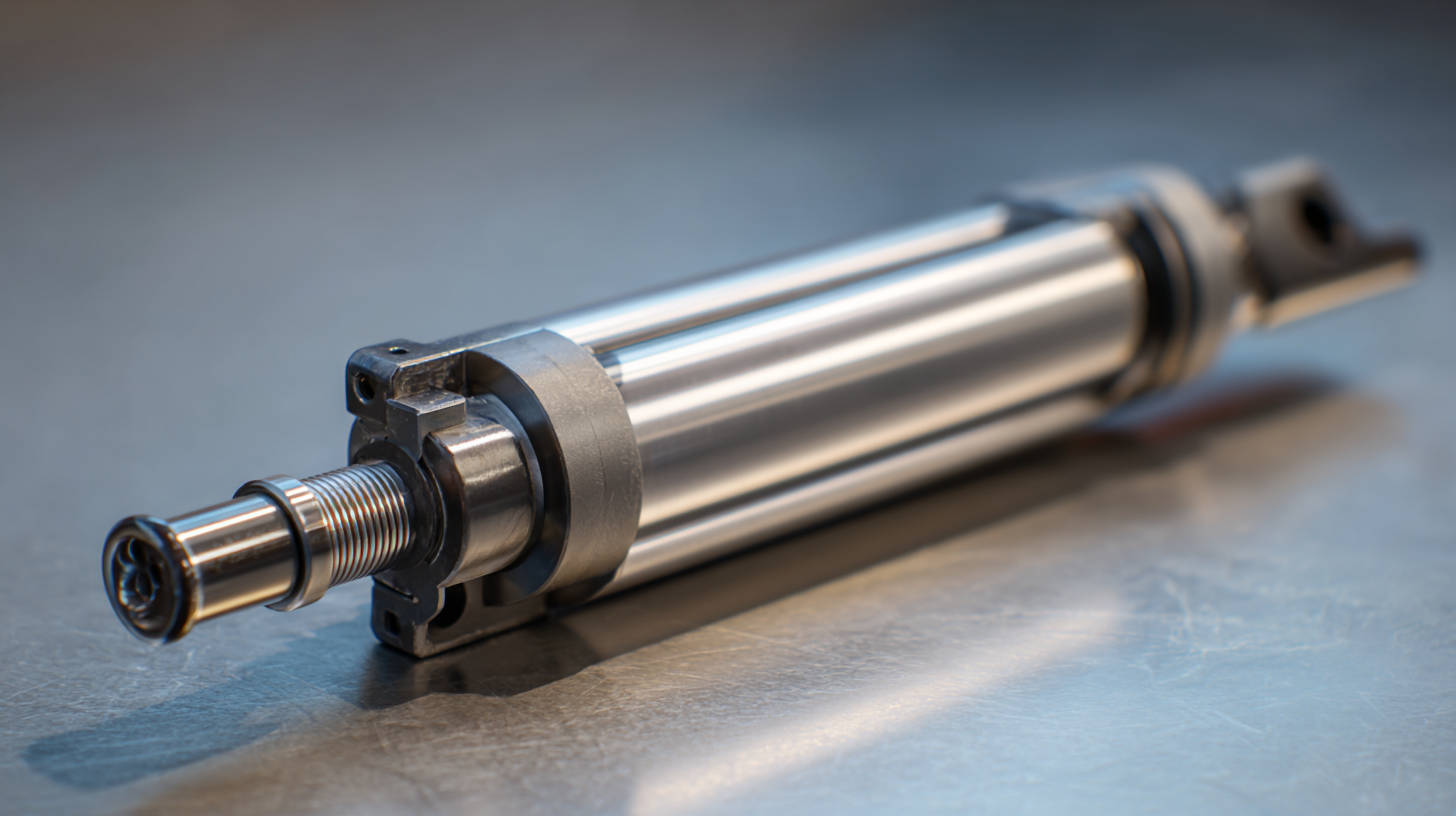

When selecting the right arm cylinder for industrial applications, several key performance factors must be considered to ensure optimal functionality and efficiency. First and foremost, the force output of the arm cylinder is critical. It should be matched to the load requirements of your specific application to prevent underperformance or mechanical failure. Additionally, understanding the stroke length is vital; it must accommodate the full range of motion needed in the operation while maintaining precision.

Another important factor is the operating environment of the arm cylinder. Conditions such as temperature fluctuations, exposure to harsh chemicals, or the presence of dust and debris can significantly affect the durability and operational lifespan of the cylinder. Therefore, selecting a cylinder with appropriate seals and materials that can withstand these conditions is essential. Furthermore, considerations related to the actuation method—such as pneumatic or hydraulic systems—can influence both performance and maintenance requirements, making it crucial to choose a system that aligns with the overall machinery design and operational goals.

| Performance Factor | Description | Consideration |

|---|---|---|

| Cylinder Type | Different types include single-acting, double-acting, and telescopic | Choose based on application requirements and space constraints |

| Bore Size | The diameter of the cylinder which influences force generation | Larger bore sizes provide more force but require more hydraulic fluid |

| Pressure Rating | Maximum pressure the cylinder can safely operate under | Ensure compatibility with your hydraulic system pressure |

| Stroke Length | Distance the cylinder can extend and retract | Determine necessary movement range for application needs |

| Mounting Style | Different mounting styles possible such as flange, pivot, and trunnion | Select based on installation space and mechanical design |

| Operating Temperature | The range of temperatures the cylinder can function in | Choose materials that can withstand specific environmental conditions |

| Material | Common materials include aluminum, steel, and composite materials | Consider durability, weight, and corrosion resistance |

Selecting the right arm cylinder for industrial applications requires careful consideration of materials and design. The material choice plays a critical role in the durability and performance of the cylinder.

Common materials include aluminum, steel, and composite materials, each with distinct advantages. Aluminum is lightweight and resistant to corrosion, making it ideal for applications where weight reduction is crucial. Steel, on the other hand, offers superior strength and is suitable for heavy-duty applications that demand high tensile strength and durability.

In addition to the material, the design of the arm cylinder must align with the specific operational requirements. Factors such as stroke length, piston diameter, and mounting options should all be evaluated. A cylinder with a longer stroke can accommodate greater movement, which is essential in dynamic environments. Moreover, the design should consider the mounting configuration—whether it's a fixed or pivoting mount—as this can significantly influence the cylinder's effectiveness in the intended application. By thoroughly assessing these material and design choices, businesses can ensure optimal performance and longevity for their industrial arm cylinders.

When selecting an arm cylinder for industrial applications, size and stroke length are critical factors that directly influence performance. The size of the cylinder must correspond to the load it will handle; undersized cylinders can lead to premature wear or failure, while oversized units may incur unnecessary costs and space constraints. To ensure optimal operation, it's essential to evaluate the maximum load requirements, the environment in which the cylinder will operate, and the available mounting space.

Stroke length is equally important, as it determines the range of motion and efficiency of the application. A cylinder with an inadequate stroke length may not fully execute the desired tasks, leading to operational delays and reduced productivity. Conversely, excessively long strokes can complicate movements and reduce overall efficiency. Accurately assessing the needs of your application—considering both the distance the load must travel and the speed at which it needs to move—will help you choose a cylinder with the appropriate stroke length, ensuring that it meets both performance expectations and operational demands.

This chart illustrates the relationship between the size and stroke length of arm cylinders in various industrial applications. The data represents typical sizes and stroke lengths used in heavy machinery, showcasing optimal performance ranges.

When selecting the right arm cylinders for industrial applications, it's essential to avoid common pitfalls that could lead to inefficiencies or operational failures. One critical mistake is not considering the environmental conditions where the cylinders will be used. For instance, exposure to moisture or extreme temperatures can significantly impact the performance and lifespan of an arm cylinder.

According to industry reports, around 30% of failures in hydraulic systems can be traced back to inappropriate cylinder selection based on environmental factors.

Another frequent oversight is underestimating the load requirements. Selecting a cylinder with insufficient force capabilities can lead to mechanical stress, resulting in quicker wear and possible breakdowns. It's advisable to calculate the maximum load and choose a cylinder that exceeds this capacity by a safety margin of at least 25%, as emphasizing reliability can substantially reduce maintenance costs in the long run.

Tips: Always consult manufacturer specifications and utilize simulation tools for accurate load analysis. Additionally, avoid rushing the selection process; taking the time to analyze each requirement can save future headaches and expenses.