+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

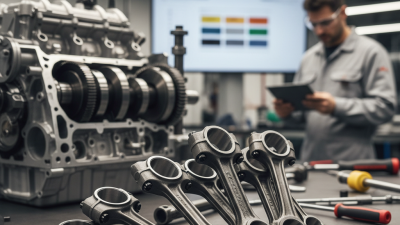

Connecting rods play a crucial role in the performance of internal combustion engines, acting as the vital link between the pistons and the crankshaft. According to a report by the Engine Manufacturers Association, connecting rods account for approximately 10-15% of the total weight of an engine’s reciprocating components, making their construction and material selection vital for enhancing overall engine efficiency. The geometry, length, and material of connecting rods significantly influence engine dynamics, including weight distribution, vibration characteristics, and ultimately, power output.

In recent studies, it has been demonstrated that optimizing connecting rod design can lead to substantial improvements in engine performance. For instance, using high-strength alloys or composite materials can reduce weight while increasing the structural integrity of connecting rods, resulting in a decrease in inertia and enhanced responsiveness. As engines evolve toward higher performance thresholds, understanding the intricate relationship between connecting rods and engine efficiency becomes increasingly critical. Therefore, a comprehensive understanding of connecting rods not only aids in engine design and tuning but also contributes to achieving better fuel economy and reduced emissions in modern automotive engineering.

Connecting rods play a crucial role in the mechanics of an engine, acting as the link between the piston and the crankshaft. Their ability to withstand high tension and compressive loads is vital for optimal engine performance. According to industry reports, connecting rods need to maintain exceptional rigidity while being lightweight to minimize the overall weight of the engine. This balance is essential as it directly affects the engine's efficiency, responsiveness, and power output. Materials such as high-strength steel and aluminum alloys are commonly utilized in advanced engine designs to enhance performance while ensuring durability.

When considering connecting rods, one significant tip is to pay attention to their length and design. Longer connecting rods can lead to a more favorable piston motion, resulting in increased engine efficiency and power. However, they can also increase the engine's overall height, which may impact the layout of the engine compartment. Additionally, optimizing the connecting rod-to-stroke ratio is essential; an ideal ratio typically falls between 1.5 and 2.0, providing a balance between performance and mechanical stress.

Another critical aspect to understand is the importance of connecting rod bearings. Quality bearings reduce friction and wear, allowing the engine to operate smoothly and efficiently. Regular checks on these components can prevent catastrophic failures and prolong engine life. Reports indicate that engines with well-maintained connecting rod assemblies can achieve a 5-10% improvement in fuel efficiency, showcasing the significance of each element in engine mechanics.

This chart illustrates the impact of connecting rod length on engine performance metrics such as horsepower, torque, and RPM. Understanding these relationships helps in optimizing engine design for better efficiency and power delivery.

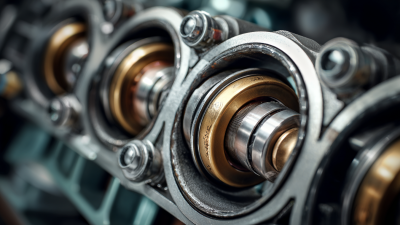

Connecting rods play a critical role in engine performance, serving as the crucial link between the piston and the crankshaft. The choice of materials used in their manufacturing significantly impacts their strength and overall efficiency. Traditionally, connecting rods were made from cast iron, which, while providing satisfactory strength, lacked the weight benefits essential for modern performance enhancements. Recent trends show a shift towards the use of high-strength steel alloys and aluminum alloys for connecting rod production. According to a study by the Society of Automotive Engineers (SAE), utilizing aluminum in connecting rod manufacturing can reduce weight by up to 30%, leading to improved fuel efficiency and engine responsiveness.

Moreover, advanced materials such as carbon fiber composites are being explored for high-performance applications. These materials offer not only reduced weight but also enhanced stiffness and fatigue resistance, making them ideal for high-revving engines. A report from the International Council on Clean Transportation indicates that reducing engine weight through superior material use can lead to a 5-10% increase in overall vehicle efficiency. As the automotive industry continues to prioritize environmental impact and performance, the evolution of materials used in connecting rod manufacturing will play a pivotal role in shaping future engine design and capability.

The relationship between connecting rod length and engine performance is a crucial aspect in engine design that significantly impacts efficiency, power output, and overall vehicle dynamics. Research illustrates that longer connecting rods often facilitate a more optimal angle of attack during the engine’s cycle, which can enhance the combustion process. According to a study published in the "Journal of Automotive Engineering", engines fitted with longer connecting rods can generate up to 5% more power compared to those with shorter alternatives, primarily because of reduced side loading on the pistons and improved mechanical efficiency.

Moreover, the length of the connecting rod influences the engine's stroke-to-bore ratio, which is a critical factor in defining an engine's performance characteristics. A longer rod can promote a higher rev range due to its contribution to a smoother arc of motion, allowing the piston to maintain a more controlled velocity as it moves through the cylinder. This is particularly beneficial in high-performance applications where engine speed is paramount. Data from the "International Journal of Engine Research" indicates that vehicles with a longer connecting rod design typically exhibit improved throttle response and increased torque availability throughout the rev range, making them more desirable for performance-oriented driving conditions.

In conclusion, understanding the implications of connecting rod length on engine performance is essential for engineers aiming to optimize power and efficiency in modern automotive applications.

The design of connecting rods is a critical factor in determining an engine’s RPM and power output. Connecting rods serve as the link between the pistons and the crankshaft, translating the linear motion of the pistons into rotational motion that powers the vehicle. The length, material, and overall design of the connecting rods directly influence the engine's ability to rev efficiently and generate power. For instance, longer connecting rods can reduce the angle between the connecting rod and the crankshaft, which can enhance the engine's ability to generate higher RPMs due to minimized friction and better alignment in the stroke cycle.

Moreover, the choice of materials and the design structure also play pivotal roles in performance. Lightweight materials like aluminum and forged steels help reduce the overall weight of the engine components, improving response time and allowing for higher RPM capabilities. A well-designed connecting rod, incorporating features such as optimized geometry and sufficient cross-sectional area, can withstand higher stress without deforming, thus increasing the power output. Engineers often focus on these design aspects to maintain durability while enhancing the engine's performance metrics, leading to improved acceleration and efficiency in a range of driving conditions.

| Connecting Rod Length (mm) | Material | Weight (g) | Max RPM | Power Output (HP) |

|---|---|---|---|---|

| 140 | Aluminum | 450 | 8000 | 220 |

| 150 | Steel | 550 | 9500 | 300 |

| 160 | Titanium | 400 | 11000 | 350 |

| 130 | Forged Steel | 600 | 7500 | 180 |

| 155 | Aluminum Alloy | 470 | 8500 | 250 |

The connecting rod is a crucial component in an internal combustion engine, serving as the link between the piston and the crankshaft. Understanding the failure modes of connecting rods is essential for optimizing engine performance and preventing catastrophic failures. Common failure modes include fatigue, bending, and material fracture, often resulting from excessive loads, poor lubrication, or manufacturing defects. A report from the Society of Automotive Engineers (SAE) indicates that connecting rod failures account for approximately 12% of total engine failures, emphasizing the need for rigorous analysis and preventive measures.

Preventative strategies to mitigate connecting rod failures involve a combination of material selection, design optimization, and maintenance practices. Using high-strength alloys can significantly enhance fatigue resistance, thereby reducing the risk of bending or fracture under high-stress conditions. Moreover, finite element analysis (FEA) has become an essential tool in the design phase, allowing engineers to simulate and evaluate the stress distribution within connecting rods during engine operation. A study published in the Journal of Mechanical Engineering highlights that implementing these advanced analysis methods can decrease the occurrence of fatigue-related failures by up to 30%. Regular inspection and maintenance of lubrication systems also play a vital role, as maintaining optimal lubrication reduces wear and friction, further extending the lifespan of connecting rods.