+86 13794985240

+86 13794985240

CAT Excavator Bucket For CAT336 CAT324 Bucket Manufacture

Introduction to Excavator Buckets

Excavator buckets are vital attachments that significantly enhance the functionality and versatility of excavators. Designed for a variety of tasks, these buckets are essential tools in construction, landscaping, mining, and demolition projects. In this article, we will explore the function, features, and importance of excavator buckets.

Function of Excavator Buckets

The primary function of an excavator bucket is to excavate, scoop, and transport materials such as soil, gravel, sand, and debris. Depending on the design and size of the bucket, it can perform a range of tasks:

Digging: Buckets are used to dig trenches, foundations, and holes in the ground. Their shape and design allow for efficient penetration into various types of soil.

Scooping: Excavator buckets can scoop up loose materials, making them ideal for loading trucks or transferring materials to different locations.

Grading and Leveling: Some buckets are specifically designed for grading and leveling surfaces, allowing operators to create smooth and even ground.

Key Features

Material Composition: Excavator buckets are typically constructed from high-strength steel to withstand the rigors of heavy-duty operations. Many buckets feature reinforced edges or wear plates to enhance durability and extend their lifespan.

Variety of Designs: Buckets come in various shapes and sizes, including standard buckets, trenching buckets, and rock buckets, each tailored for specific applications. The choice of bucket depends on the type of material being handled and the nature of the job.

Attachment Mechanism: Buckets are equipped with quick couplers or pin-on attachment systems, allowing for easy attachment and detachment from the excavator. This feature enhances the versatility of the machine, enabling operators to switch between different attachments as needed.

Importance in Excavator Performance

Excavator buckets are crucial for several reasons:

Efficiency: The right bucket design can significantly improve the efficiency of excavation and material handling tasks, allowing operators to complete jobs more quickly and effectively.

Versatility: With various bucket types available, excavators can be adapted for a wide range of applications, from digging and grading to demolition and material transport.

Cost-Effectiveness: By using the appropriate bucket for specific tasks, operators can reduce wear on the excavator and minimize fuel consumption, leading to lower operational costs.

Maintenance Considerations

To ensure the longevity and performance of excavator buckets, regular maintenance is essential. Key maintenance practices include:

Regular Inspections: Check buckets for signs of wear, cracks, or damage. Early detection of issues can prevent more significant problems and costly repairs.

Cleaning: Keep the bucket clean from debris and material buildup to prevent corrosion and maintain optimal performance.

Sharpening Edges: Regularly sharpen the cutting edges of the bucket to ensure efficient digging and material handling.

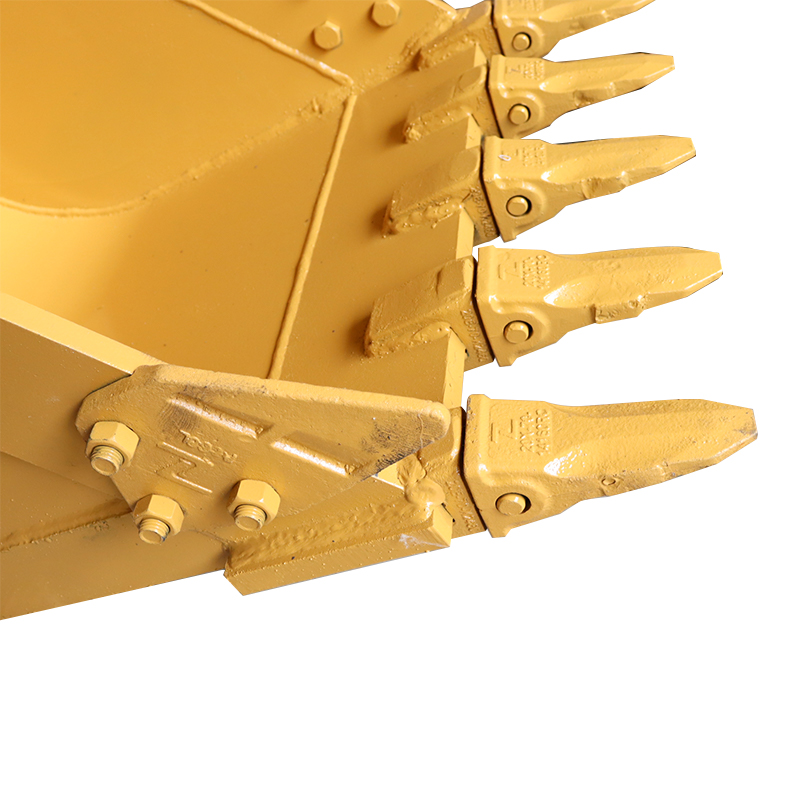

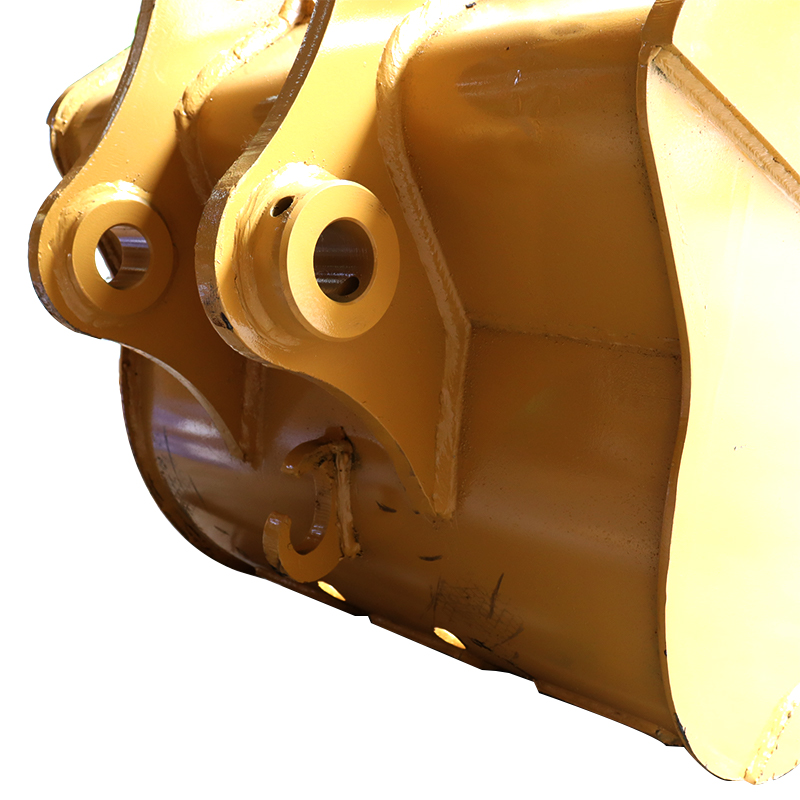

Product Display

-

excavator bucket1

-

excavator bucket2

-

excavator bucket3

-

excavator bucket4