+86 13794985240

+86 13794985240

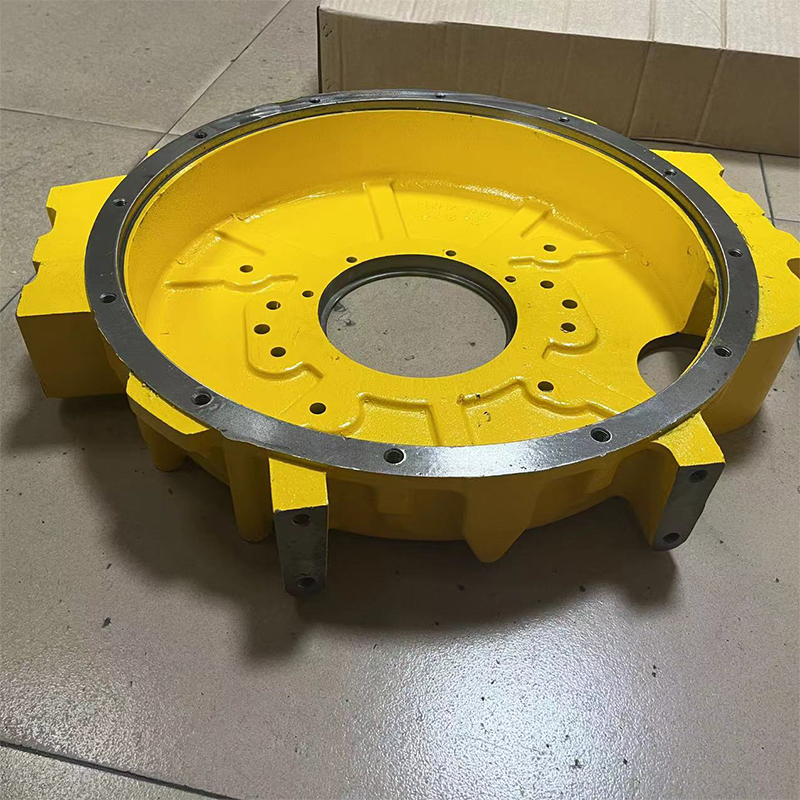

Flywheel Housing 125-2965 For Excavator CAT312B 320B 320D Wheel Loader 910G 1252965

Engine Flywheel Housings Little Tips

The engine flywheel housing, also known as the bell housing, is a critical component in an internal combustion engine system, particularly in vehicles and heavy machinery like excavators. It serves several important functions related to the engine’s operation and overall performance. Here’s a detailed overview of the flywheel housing and its role in an engine.

Basic Functionality

The flywheel housing is a protective casing that encloses the flywheel and connects the engine to the transmission. It plays a vital role in housing the components that facilitate the transfer of power from the engine to the drivetrain. The flywheel itself is a heavy, rotating disc that helps to smooth out the engine’s power delivery and maintain momentum.

Key Functions

Power Transfer: The flywheel housing provides a mounting point for the transmission, allowing for the efficient transfer of power from the engine to the wheels or tracks of the vehicle.

Protection: It protects the flywheel and other internal components from dirt, debris, and damage, ensuring reliable operation.

Alignment: The housing helps maintain proper alignment between the engine and the transmission, which is crucial for smooth operation and reducing wear on components.

Design and Construction

Flywheel housings are typically made from durable materials such as cast iron or aluminum, which can withstand the high stresses and temperatures generated during engine operation. The design of the housing may vary depending on the engine type and application, but it generally features:

Mounting Points: For securing the transmission and other components.

Access Ports: For maintenance and inspection of the flywheel and clutch assembly.

Sealing Features: To prevent oil leaks and protect against contaminants.

Role in Engine Performance

The flywheel housing contributes to the overall performance of the engine by:

Reducing Vibration: The flywheel helps to dampen engine vibrations, leading to smoother operation and less stress on the drivetrain.

Enhancing Torque Delivery: By storing rotational energy, the flywheel allows for more consistent torque delivery, improving acceleration and responsiveness.

Maintenance Considerations

Regular inspection and maintenance of the flywheel housing are essential to ensure optimal engine performance. Key maintenance practices include:

Checking for Cracks or Damage: Inspecting the housing for any signs of wear or damage that could affect its integrity.

Monitoring for Leaks: Ensuring that there are no oil leaks around the housing, which could indicate a problem with the seals or gaskets.

Cleaning: Keeping the housing clean from dirt and debris to prevent contamination of the internal components.

Product Display

-

Flywheel Housing 125-2965 For Excavator CAT312B 320B 320D Wheel Loader 910G 1252965

-

Flywheel Housing 125-2965 For Excavator CAT312B 320B 320D Wheel Loader 910G 1252965 01

-

Flywheel Housing 125-2965 For Excavator CAT312B 320B 320D Wheel Loader 910G 1252965 02