+86 13794985240

+86 13794985240

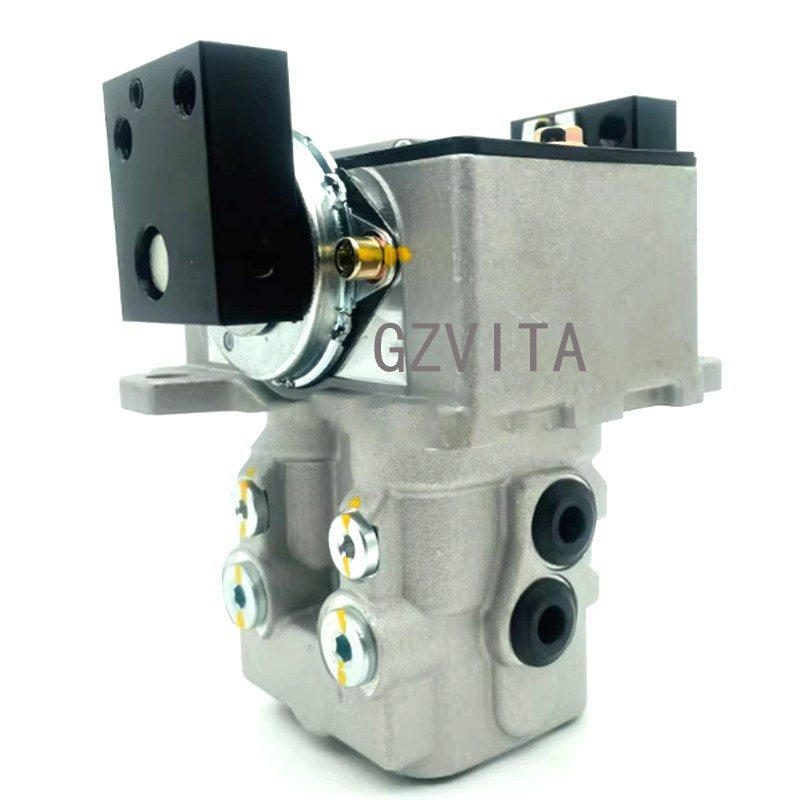

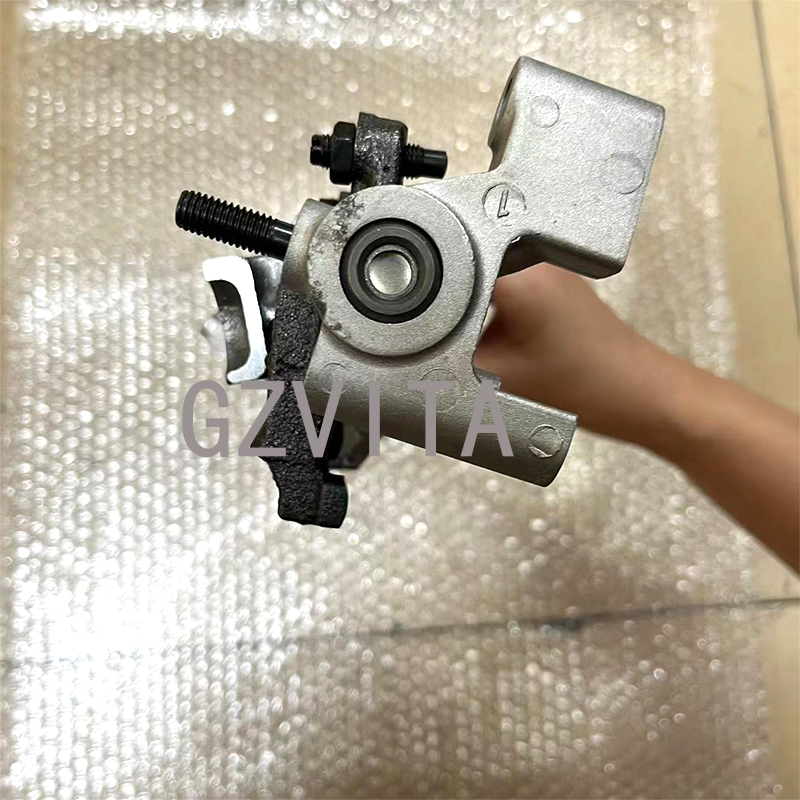

High Quality OEM Rocker Arm Assembly For 4TNV94 Engine 129907-11341

Introduction to Rocker Arm Assembly in an Engine

The rocker arm assembly is a critical component of an internal combustion engine’s valvetrain system. Its primary function is to convert the linear motion of the camshaft into the rotational motion required to open and close the engine’s intake and exhaust valves.

This process is essential for the engine’s operation, as it regulates the flow of air and fuel into the combustion chamber and the expulsion of exhaust gases.

Key Components of the Rocker Arm Assembly

Rocker Arms: These are lever-like components that pivot on a shaft or individual mounts. When the camshaft rotates, it pushes against one end of the rocker arm, causing the other end to push down on the valve stem, opening the valve.

Push Rods: In overhead valve (OHV) engines, push rods connect the camshaft to the rocker arms. They transmit the motion from the camshaft to the rocker arms.

Camshaft: The camshaft is responsible for controlling the timing and duration of valve openings. Its lobes push against the push rods or directly against the rocker arms, depending on the engine design.

Valve Springs: These springs close the valves when the rocker arms are not applying force. They ensure that the valves return to their closed position quickly after being opened.

Adjustable Lifters or Tappets: These components maintain the proper clearance between the rocker arms and the valves, ensuring efficient operation and preventing excessive wear.

Functionality

The rocker arm assembly plays a vital role in the engine’s performance. The timing and lift of the valves directly affect the engine’s efficiency, power output, and emissions.

Properly designed rocker arms can enhance the engine’s breathing capabilities, allowing for better airflow and improved combustion.

Types of Rocker Arm Assemblies

Overhead Valve (OHV): In this design, the rocker arms are located above the valves, and the push rods transfer motion from the camshaft.

Overhead Cam (OHC): In OHC engines, the camshaft is located directly above the valves, eliminating the need for push rods. This design can lead to more precise valve timing and reduced weight.

Dual Overhead Cam (DOHC): This configuration features two camshafts per cylinder head—one for intake valves and one for exhaust valves—allowing for more complex valve timing and improved performance.