+86 13794985240

+86 13794985240

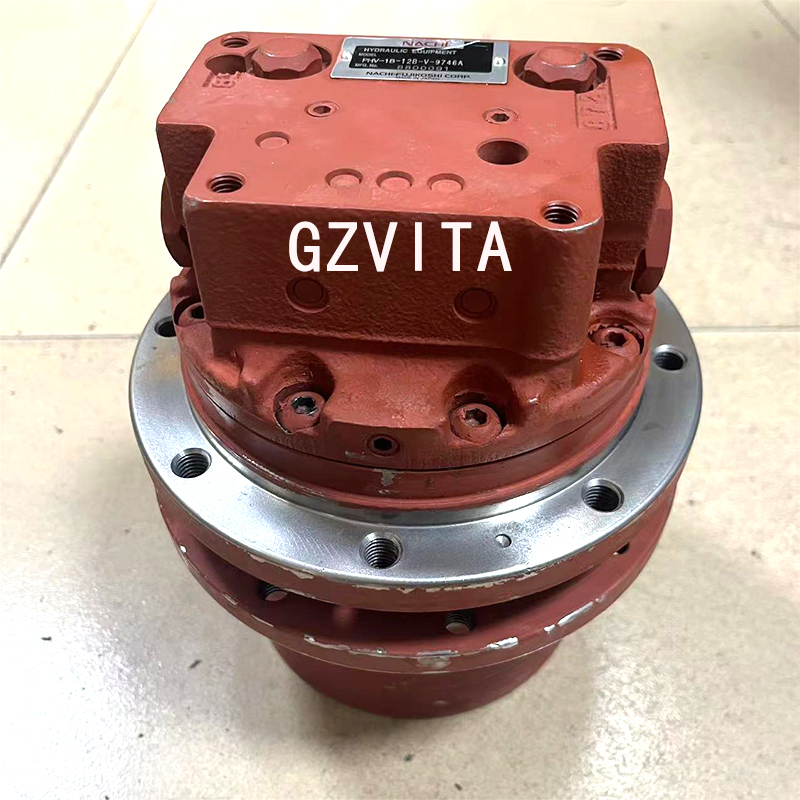

Mini Excavator PC07-2 Final Drive PHV-1B-12B-V-9746A

The Installation Data of the Final Drive in Excavators

The final drive is a critical component in excavators, responsible for transmitting power from the hydraulic motor to the tracks or wheels, enabling movement and operation. Proper installation of the final drive is essential for optimal performance and longevity of the excavator. Here are key considerations and data related to the installation of the final drive in excavators:

- Preparation and Inspection

Component Inspection: Before installation, inspect the final drive and associated components for any signs of damage or wear. Ensure that all parts are clean and free from debris.

Alignment Check: Verify that the mounting surfaces are clean and properly aligned to prevent misalignment during installation.

- Installation Steps

Positioning: Carefully position the final drive onto the excavator’s frame, ensuring that it aligns with the mounting points.

Bolting: Use the specified torque settings for the bolts to secure the final drive. Refer to the manufacturer’s specifications for the correct torque values to avoid over-tightening or under-tightening.

Hydraulic Connections: Connect the hydraulic lines to the final drive, ensuring that they are properly secured and free from leaks. Use appropriate fittings and seals as recommended by the manufacturer.

- Testing and Calibration

Functional Testing: After installation, conduct a functional test of the final drive. Check for smooth operation and listen for any unusual noises that may indicate issues.

Calibration: If applicable, calibrate the final drive according to the manufacturer’s guidelines to ensure optimal performance and efficiency.

- Maintenance Considerations

Regular Inspections: Schedule regular inspections of the final drive to check for wear and tear, fluid levels, and any signs of leakage.

Lubrication: Ensure that the final drive is properly lubricated according to the manufacturer’s recommendations to prevent overheating and premature wear.

- Documentation

Installation Records: Keep detailed records of the installation process, including torque settings, hydraulic connections, and any adjustments made. This documentation can be valuable for future maintenance and troubleshooting.

Conclusion

The installation of the final drive in excavators is a critical process that requires attention to detail and adherence to manufacturer specifications. Proper installation ensures the efficient operation of the excavator, contributing to its overall performance and longevity. By following the outlined steps and maintaining regular inspections, operators can maximize the effectiveness of their excavators and minimize downtime.