+86 13794985240

+86 13794985240 Revolutionizing Production: New Equipment for Engine Connecting Rod Bearings

In the ever-evolving landscape of automotive manufacturing, innovation is key to maintaining competitive advantage and ensuring product quality. Recently, a significant advancement has been made in the production of engine connecting rod bearings, crankshaft bearings and thrust washer ,a critical component in engine performance and longevity.

The Importance of Connecting Rod Bearings

Connecting rod bearings play a vital role in the engine’s operation. They facilitate the smooth movement of the connecting rods, which link the pistons to the crankshaft. High-quality bearings are crucial for reducing friction, minimizing wear, and ensuring optimal engine performance. As automotive technology advances, the demand for more efficient and durable connecting rod bearings has surged, prompting manufacturers to seek innovative solutions.

Introducing Cutting-Edge Production Equipment

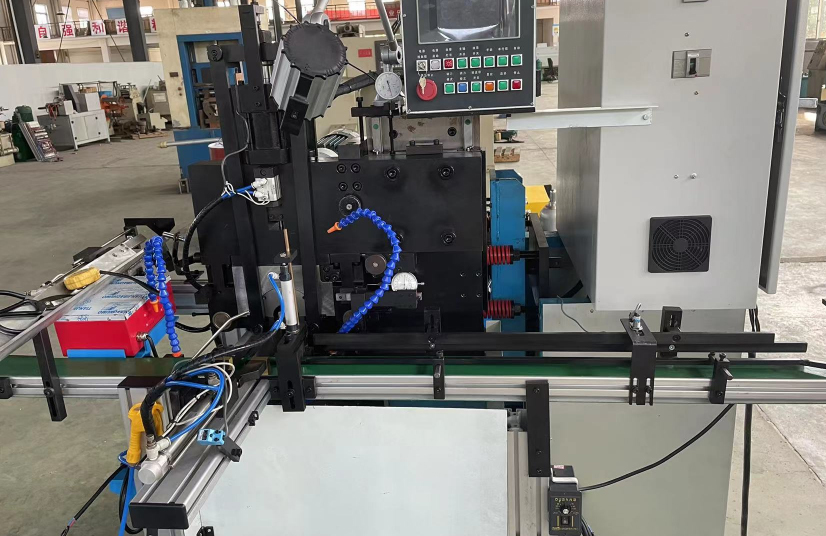

To meet this growing demand, a leading manufacturer has unveiled a state-of-the-art production line specifically designed for the fabrication of engine connecting rod bearings. This new equipment incorporates advanced technologies such as precision machining, automated assembly, and real-time quality control systems.

Precision Machining: The new machinery utilizes CNC (Computer Numerical Control) technology, allowing for unparalleled accuracy in the machining process. This ensures that each bearing is produced to exact specifications, reducing the likelihood of defects and enhancing overall performance.

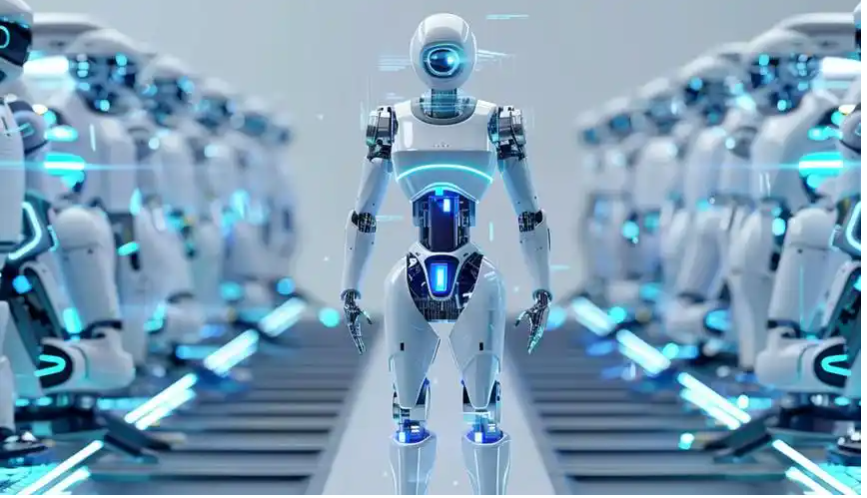

Automated Assembly: Automation is a game-changer in manufacturing. The new production line features robotic systems that streamline the assembly process, significantly increasing efficiency and reducing labor costs. This automation not only speeds up production but also minimizes human error, leading to higher quality products.

Real-Time Quality Control: Quality assurance is paramount in automotive manufacturing. The new equipment is equipped with advanced sensors and monitoring systems that provide real-time feedback on the production process. This allows for immediate adjustments to be made, ensuring that every bearing meets stringent quality standards before it leaves the factory.

Benefits of the New Equipment

The introduction of this new production equipment offers several key benefits:

Increased Production Capacity: With enhanced efficiency and automation, manufacturers can significantly increase their output, meeting the rising demand for connecting rod bearings ,crankshaft bearings in a timely manner.

Improved Product Quality: The precision machining and real-time quality control systems ensure that each bearing is manufactured to the highest standards, resulting in improved engine performance and longevity.

Cost-Effectiveness: By reducing labor costs and minimizing waste through efficient production processes, manufacturers can achieve better profit margins while offering competitive pricing to customers.

Looking Ahead

As the automotive industry continues to evolve, the introduction of new equipment for the production of engine connecting rod bearings marks a significant step forward. This innovation not only enhances manufacturing capabilities but also contributes to the overall improvement of engine performance and reliability.

We invite you to explore our offerings and place your order with confidence. Thank you for choosing us as your trusted partner in construction machinery components. We look forward to serving you.