+86 13794985240

+86 13794985240

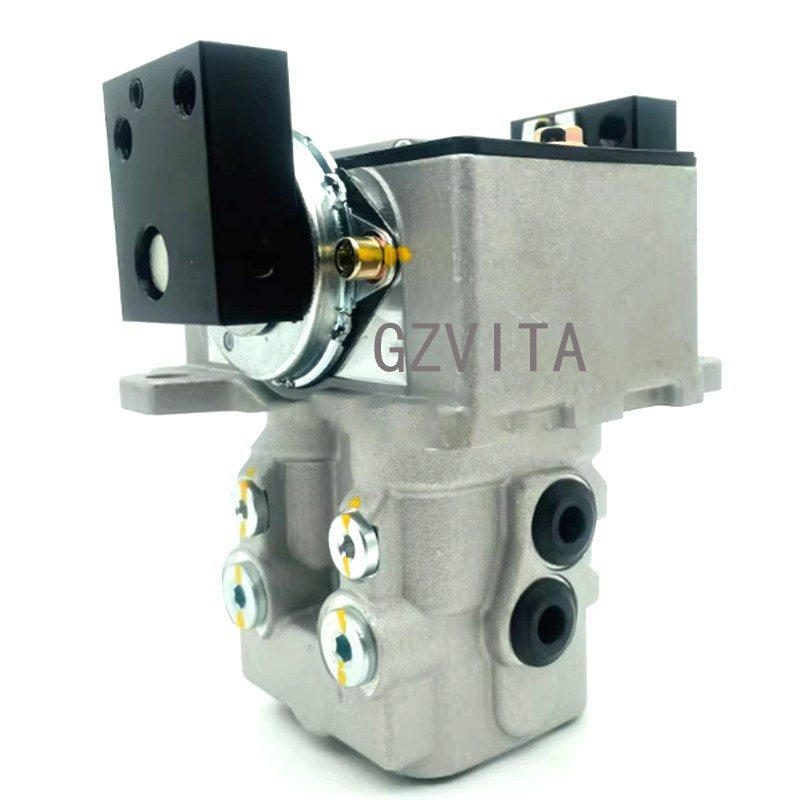

OEM New Hydraulic Pump K7SP36/K7V28-11VR-922A/25 Main pump

Introduction to OEM Hydraulic Pumps for Excavators

When it comes to excavators, the hydraulic pump is a critical component that plays a vital role in the machine’s overall performance.

The quality of the hydraulic pump can significantly impact the efficiency, reliability, and longevity of the excavator.

Key Considerations for OEM Hydraulic Pumps:

Quality Assurance:

OEM (Original Equipment Manufacturer) pumps are designed and manufactured to meet the specific standards and specifications set by the excavator manufacturer. This ensures that the pump is compatible with the machine and performs optimally.

OEM parts typically undergo rigorous testing and quality control processes, which can lead to better performance and reliability compared to aftermarket alternatives.

Performance:

OEM hydraulic pumps are engineered to provide the correct flow and pressure required for the excavator’s hydraulic system. This ensures that all hydraulic functions, such as boom movement, arm extension, and bucket operation, work smoothly and efficiently.

The precision engineering of OEM pumps can lead to improved fuel efficiency and reduced operational costs over time.

Durability and Longevity:

OEM hydraulic pumps are built with high-quality materials that are designed to withstand the demanding conditions of construction and excavation work. This can result in a longer lifespan compared to non-OEM pumps, which may not be built to the same standards.

Using OEM parts can help prevent premature wear and tear on other hydraulic components, reducing the risk of costly repairs and downtime.

Warranty and Support:

OEM hydraulic pumps often come with a warranty that covers defects and performance issues, providing peace of mind for operators and fleet managers.

Additionally, OEM parts are supported by the manufacturer’s service network, ensuring that assistance and replacement parts are readily available.

Compatibility:

Since OEM pumps are specifically designed for particular excavator models, they ensure perfect compatibility with the hydraulic system.

This minimizes the risk of installation issues and operational problems that can arise from using non-OEM parts.

Conclusion

In summary, the quality of an OEM new hydraulic pump for an excavator is generally superior to that of aftermarket options.

The benefits of using OEM pumps include enhanced performance, durability, compatibility, and support, all of which contribute to the overall efficiency and reliability of the excavator.

For operators and fleet managers looking to maintain their equipment’s performance and longevity, investing in OEM hydraulic pumps is often the best choice.