+86 13794985240

+86 13794985240

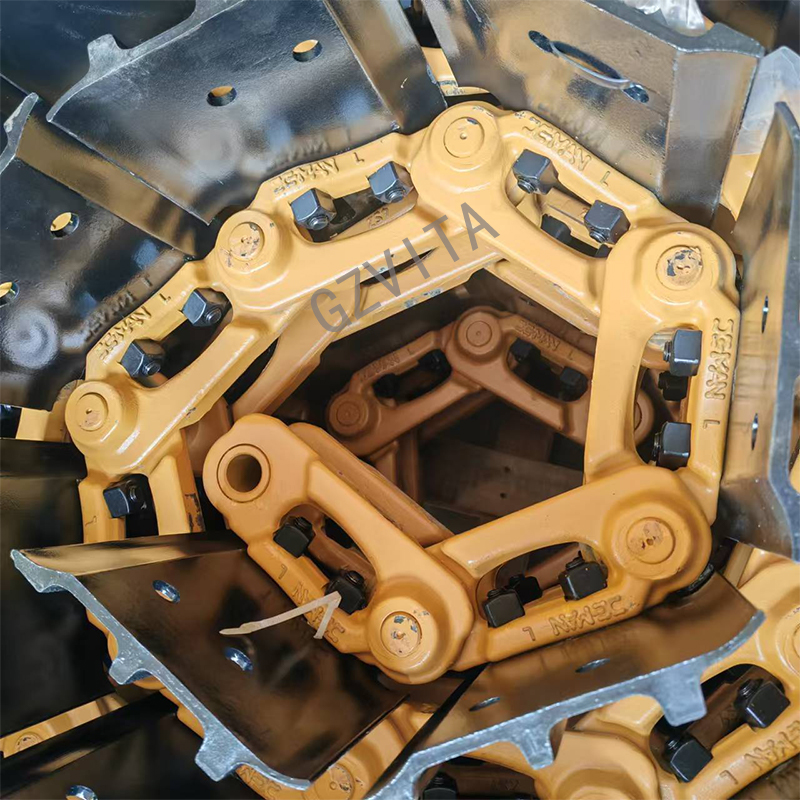

Track link Assembly for Excavator Kubota U55 RD411-22203

Introduction to Excavator Tracks/Track link

Excavator track link assembly, also known as track chains, are a fundamental component of an excavator’s undercarriage system. They provide the necessary traction and stability for the machine to move across various terrains, making them essential for the performance and efficiency of the excavator.

Key Functions

Mobility: The primary function of excavator tracks is to enable movement. Unlike wheeled vehicles, tracks distribute the weight of the excavator over a larger surface area, allowing it to traverse soft, uneven, or muddy ground without sinking. This capability is crucial for construction, demolition, and landscaping applications.

Traction: Tracks provide superior traction compared to wheels, especially on slippery or loose surfaces. The design of the tracks, with their interlocking links and tread patterns, enhances grip and stability, allowing the excavator to climb slopes and navigate challenging terrains effectively.

Support and Stability: Tracks help support the weight of the excavator and its load, ensuring stability during operation. This is particularly important when the machine is working on inclines or uneven surfaces, as it reduces the risk of tipping or losing balance.

Design and Durability

Excavator tracks are typically made from high-strength steel or rubber, designed to withstand the harsh conditions of construction sites. Steel tracks are more common in heavy-duty applications due to their durability and resistance to wear, while rubber tracks are often used in lighter machines for their quieter operation and reduced ground disturbance.

The design of the tracks includes various components, such as:

Track Links: The individual segments that connect to form the continuous loop of the track.

Track Rollers: These support the weight of the excavator and help guide the movement of the tracks.

Sprockets: The toothed wheels that engage with the track links, providing the necessary drive to move the excavator.

Maintenance and Importance

Regular maintenance of excavator tracks is essential for ensuring their longevity and performance. This includes:

Inspection for Wear: Regularly checking for signs of wear, such as cracks or elongation of the track links.

Tension Adjustment: Ensuring that the tracks are properly tensioned to prevent slippage or excessive wear.

Cleaning: Keeping the tracks free from debris and mud to maintain optimal performance.

Neglecting maintenance can lead to premature wear, reduced efficiency, and costly repairs.

Product Display

-

Track link1

-

Track link2

-

Track link3

-

Track link4