+86 13794985240

+86 13794985240

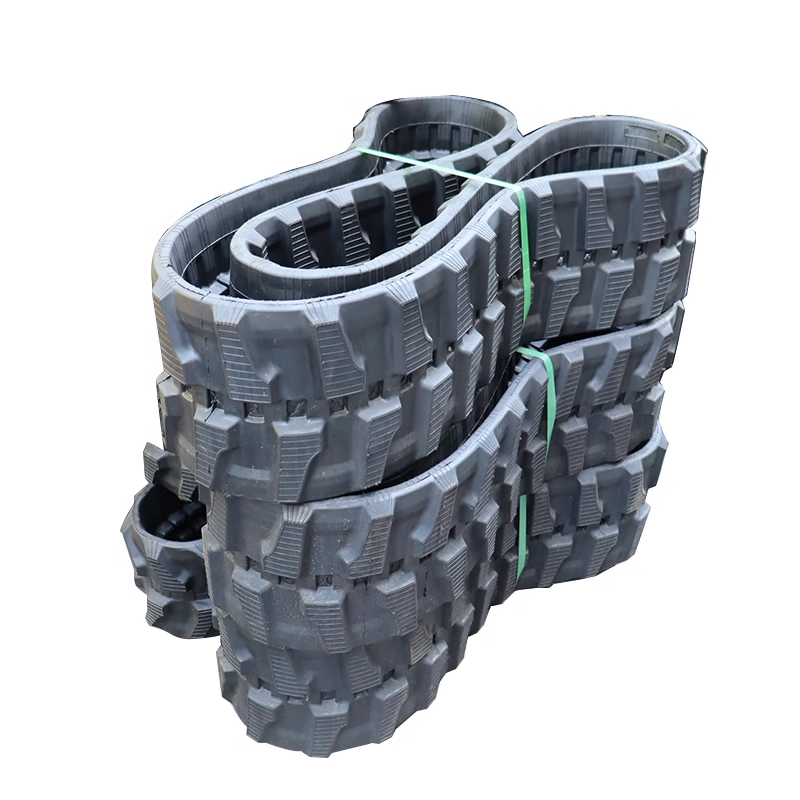

Undercarriage Parts Rubber track For Excavator Rubber chain

The Importance of Machinery Rubber Tracks

Rubber tracks are a critical component in many types of machinery, particularly in excavators, mini-excavators, and other construction equipment. They provide several advantages over traditional steel tracks and wheels, making them an essential feature for various applications. In this blog, we will explore the importance of rubber tracks in machinery, focusing on their benefits, applications, and maintenance considerations.

Benefits of Rubber Tracks

Enhanced Traction: Rubber tracks offer superior traction on various surfaces, including mud, sand, and uneven terrain. The design of the tracks allows for better grip, which is essential for maintaining stability and control during operation.

Reduced Ground Pressure: Rubber tracks distribute the weight of the machinery over a larger surface area, resulting in lower ground pressure. This feature minimizes soil compaction and damage to sensitive surfaces, making rubber tracks ideal for landscaping and agricultural applications.

Improved Ride Comfort: The flexibility of rubber tracks provides a smoother ride compared to steel tracks. This reduces vibrations and operator fatigue, enhancing comfort during long hours of operation.

Lower Noise Levels: Rubber tracks operate more quietly than steel tracks, contributing to a more pleasant working environment, especially in urban areas or noise-sensitive locations.

Less Maintenance: Rubber tracks generally require less maintenance than steel tracks. They are less prone to rust and corrosion, and their design minimizes wear and tear on the undercarriage components.

Applications of Rubber Tracks

Rubber tracks are widely used in various types of machinery, including:

Excavators: Rubber tracks provide the necessary traction and stability for excavators working on soft or uneven ground, making them suitable for construction, landscaping, and demolition projects.

Mini-Excavators: These smaller machines benefit from rubber tracks due to their lightweight design and ability to navigate tight spaces while minimizing ground disturbance.

Skid Steer Loaders: Rubber tracks enhance the versatility of skid steer loaders, allowing them to operate effectively on various surfaces, including gravel, dirt, and asphalt.

Agricultural Equipment: Rubber tracks are increasingly used in agricultural machinery, such as tractors and harvesters, to reduce soil compaction and improve traction in fields.

Maintenance Considerations

To ensure the longevity and performance of rubber tracks, regular maintenance is essential. Key maintenance practices include:

Regular Inspections: Check the tracks for signs of wear, cracks, or damage. Early detection of issues can prevent more significant problems and costly repairs.

Proper Tensioning: Ensure that the tracks are properly tensioned according to the manufacturer’s specifications. Incorrect tension can lead to premature wear and reduced performance.

Cleaning: Keep the tracks clean from mud, debris, and other contaminants that can affect performance and lead to wear.

Storage: When not in use, store machinery with rubber tracks in a cool, dry place to prevent degradation from UV exposure and extreme temperatures.

Product Display

-

Undercarriage Parts Rubber track For Excavator Rubber chain

-

Undercarriage Parts Rubber track For Excavator Rubber chain 01

-

Undercarriage Parts Rubber track For Excavator Rubber chain 02